مسكن

>

Many Parts Of Milling Machine

مسكن

>

Many Parts Of Milling Machine

منتج

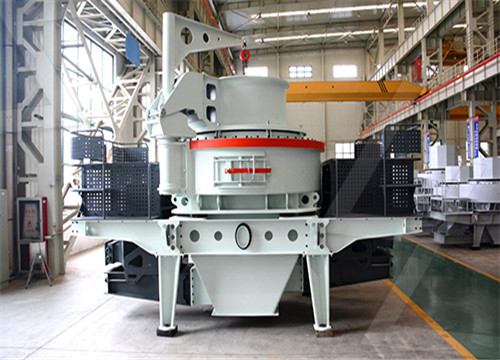

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Many Parts Of Milling Machine

Parts of Milling Machine — Different Types and Operations

2023215Milling machines have up to ten vital parts for their operation. There are different types of milling machines depending on the project you need to do. Observing the standard safety operating procedures when using a milling machine is vital. What Are

Parts Of Milling Machine And Their Functions 101ToolAdvisor

Parts of Milling MachineKnow How It WorksFinal WordsUsing a milling machine is common if you’re planning to go all-in with a metal workshop. There is no way you can do almost any metal hole fabrication jobs without a milling machine. A lathe may help you get some jobs done, but milling is a must-have machine. Working with a milling machine can be overwhelming and a daunting job as there are too many...

Milling Machine: Definition, Parts, Types, Operations

2021928The types of milling machines are the following: Column and Knee Type Milling Vertical Milling Horizontal Milling Universal

The 8 Most Important Parts of a Milling Machine CNC Masters

: 2022731

Milling Machine Parts and Their Functions YaleTools

Motor. The motor has a function to convert electric power becomes mechanical power, so

√ Milling Machine : Definition, Function and Parts Teknikece

202286The main parts of the machine include base and column, knee, saddle and swivel table, power feed mechanism, table, spindle, overarm, arbor, arbor support, and

What is Milling Machine?- Parts, Operation, Diagram

Main Parts of the Milling Machine: Column and Base. Knee. Saddle and Swivel Table. Power Feed mechanism. Table. Spindle. Over Arm / Overhanging Arm. Arbor Support.

15 Different Types of Milling Machines Engineering Choice

You can produce a milling cutter, reamer, twist drill, spiral, bevel, spur, and much more from this machine. You can perform all the operations that a shaper machine does with the universal milling machine. 4. Simplex

All parts of Milling Machine slidingmotion

To make a product, various parts of milling machines are working. So it is necessary to maintain in good condition. Parts of Miling Machine 1. Base 2. Column 3. Knee 4. Table

CNC Milling Machine Parts [Complete DIY Guide]

Axes. The axes of a CNC Milling Machine allow motion using Cartesian coordinates programmed via g-code and via manual jogging from the control panel. Generally, there are 3 axes that correspond to X, Y, and Z. An

What Is Milling Machine? Main Parts of Milling

A milling machine is a machine tool that cuts metal as the workpiece is fed against a rotating multipoint cutter. The milling cutter rotates at a very high speed because of the multiple cutting edges; it cuts the metal at a very

Milling Machine: Definition, Parts, Types,

An explanation for the parts of horizontal milling machine: The explanation for the parts of horizontal milling machine is as follows. Base: It provides support to all the parts of the machine and which can absorb the

√ Milling Machine : Definition, Function and Parts Teknikece

202286The main parts of the machine include base and column, knee, saddle and swivel table, power feed mechanism, table, spindle, overarm, arbor, arbor support, and ram. We explain each part and its functions below. 1. Base and column Base and column are the main castings supporting the rest of the machine as the two are the foundations of the

Milling Machine: Definition, Parts, Operation,

The Milling Machine consists of Base, Column, Knee, Saddle, Table, Over-Arm, Spindle or Arbor, Arbor supports, Ram, and Milling Head. We will study one by one in detail. Here in this Milling machine diagram, you

Parts of Milling Machine and Their Types,Operation

2021427The cutting action of teeth on milling cutters can be quickly machined. Parts of Milling Machine The main parts of the milling machine are following: Base Column Knee Saddle Work Table Spindle

What is Milling Machine?- Parts, Operation, Diagram

Main Parts of the Milling Machine: Column and Base. Knee. Saddle and Swivel Table. Power Feed mechanism. Table. Spindle. Over Arm / Overhanging Arm. Arbor Support. Ram Let’s go through each one of them: 1. Column and Base The column is another foundation part of the milling machine. It is a mountain vertically on the base.

What Are the parts of a CNC milling machine? • 3axis Group

Milling is suitable for many different features, including threading, chamfering, slotting, etc. This makes it possible to produce complex designs using a variety of different milling operations: Surface milling, face milling, angular milling, form milling, profile milling, gear milling, etc. Discover the parts of a CNC milling machine.

15 Different Types of Milling Machines

You can produce a milling cutter, reamer, twist drill, spiral, bevel, spur, and much more from this machine. You can perform all the operations that a shaper machine does with the universal milling machine. 4. Simplex

All parts of Milling Machine slidingmotion

To make a product, various parts of milling machines are working. So it is necessary to maintain in good condition. Parts of Miling Machine 1. Base 2. Column 3. Knee 4. Table 5. Overhanging Arm/Over Arm 6. Spindle 7. Arbor 8. Arbor Support 9. Power Feed Mechanism Parts of Miling Machine Base Column Knee Table Overhanging Arm/Over Arm Spindle

What are the Types of Milling Machines KENENG

Multiple cutters can be stored in a milling machine at once. By using a spinning cutter, milling machines make it easier to remove metal fragments. The cutter’s fast rotation speeds up the process of efficiently cutting through metal. There are many different types of milling machines on the market that can be selected to meet particular needs.

Milling Machine: Classification and Parts Machine Tools

Meaning of Milling Machine: Milling is the process of removing metal by feeding the work past a rotating multipoint cutter. In milling operation the rate of metal removal is rapid as the cutter rotates at a high speed and has many cutting edges. Thus the jobs are machined at a faster rate than with single point tools and the surface finish is

CNC Milling: Definition, Processes, Applications rapiddirect

CNC milling is suitable for many materials. Common ones include: Metals: Aluminum, stainless steel, tool steel. Mild steel, Brass, Copper Plastics: ABS, Polycarbonate, Nylon Others: Ceramics, composites, phenolics Advantages and Disadvantages of CNC Milling in the Production Process

CNC Milling a Complete Guide to Understand the Process Fractory

202058Here are the most common types of milling machines: Bed-type Knee-type Ram-type Planer-type Bed-type mills The design of bed-type milling machines includes a stable machine bed. While large and heavy parts can result in instability with knee-type machines, bed-type ones can hold their ground.

What is a milling machine? TechPlanet

2022113CNC-milled parts are used in tractors to fertilizer machines. Automotive industry: Mill parts are used widely in the automotive industry. The process can be used to create milled parts from metal, plastic, or other materials. Some of the most common uses for CNC milling are manufacturing car parts, accessories, aircraft campaigns and motor

What Is Milling Machine? Main Parts of Milling

Main Parts of Milling Machine: #1. Column and Base Columns, including the base, are the main casting that supports all other parts of the milling machine. The column consists of an oil reservoir and a pump that

Milling Machine: Definition, Parts, Types,

An explanation for the parts of horizontal milling machine: The explanation for the parts of horizontal milling machine is as follows. Base: It provides support to all the parts of the machine and which can absorb the

Milling ( Machine ) Definition, Parts, Operations,

202033Main Parts of Milling ( Machine ) These are the following main parts of the Milling machine:- Image. Main Parts of Milling ( Machine ) 1. Base 2. Column 3. Knee 4. Power Feed Mechanism 5.

Milling Machine: Classification and Parts Machine Tools

Meaning of Milling Machine: Milling is the process of removing metal by feeding the work past a rotating multipoint cutter. In milling operation the rate of metal removal is rapid as the cutter rotates at a high speed and has many cutting edges. Thus the jobs are machined at a faster rate than with single point tools and the surface finish is

9 Types of Milling Machines and How They Work YaleTools

Milling machines are generally used to form certain materials according to needs, such as threads, spirals, gears, cams, drum scales, star shafts, worm shafts and others. Milling machines can make it easier to remove metal scraps through rotating cutters. The cutter rotation takes place at a high speed, which helps to cut metal efficiently.

Cutting Tool Applications, Chapter 13: Milling Methods and Machines

2020629The many types of milling machines used in manufacturing have been grouped into three general classes: — Column and knee machines — Bed-type milling machines — Special purpose machines . The objectives are to accommodate larger work, make many duplicate parts, locate holes and surfaces precisely, or to do other

CNC Milling: Definition, Processes, Applications rapiddirect

CNC milling is suitable for many materials. Common ones include: Metals: Aluminum, stainless steel, tool steel. Mild steel, Brass, Copper Plastics: ABS, Polycarbonate, Nylon Others: Ceramics, composites, phenolics Advantages and Disadvantages of CNC Milling in the Production Process

Milling Machine Market Size, Growth Global Industry Report,

The global milling machine market size was valued at USD 13.22 billion in 2018 and is projected to reach USD 16.01 billion by 2026 exhibiting a CAGR of 2.4% during the forecast period. Horizontal mills are used for systematic purposes and complicated parts; hence, they have comparatively extended tool life. Additionally, other types of

Vertical Milling Machine Yale

The vertical milling machine is a precision tool used for shaping and fabrication by the removal of stock parts, potentially drawing the operator close to or into the cutter or spindle . Yale . Environmental HealthSafety 135 College Street 203-785-3550 ehs.yale.edu . Page 1

What are the Types of Milling Machines KENENG

Multiple cutters can be stored in a milling machine at once. By using a spinning cutter, milling machines make it easier to remove metal fragments. The cutter’s fast rotation speeds up the process of efficiently cutting through metal. There are many different types of milling machines on the market that can be selected to meet particular needs.

Milling Machines Mega Guide What Are They,

Los ventiladores de 40x40mm son el tipo más común para el ventilador de capa yrefrigerar la electrónica, cajas, etc. Ventiladores de 40×40 Ventiladores de 30×30 mm Los ventiladores de 30x30mm son el tamaño

Horizontal vs. Vertical Mills: 10 Key Differences Explained

2023111Knee Mill: The machine tool of choice for many machine shops, knee mills feature a fixed spindle. The knee moves vertically on the Z-axis, and the table moves on a longitudinal X-axis and an in-and-out Y

Milling machine parts and their functions studentlesson

2020522Milling machine generally have two types of arbor supports, the first one has a small diameter bearing hole, 1-inch in maximum diameter, and the second one has a large diameter bearing hole of about 23/4 inches. This milling part contains an oil reservoir which aid the lubrication of the bearing surfaces. This arbor support is use only in the

What is a milling machine? TechPlanet

2022113CNC-milled parts are used in tractors to fertilizer machines. Automotive industry: Mill parts are used widely in the automotive industry. The process can be used to create milled parts from metal, plastic, or other materials. Some of the most common uses for CNC milling are manufacturing car parts, accessories, aircraft campaigns and motor