مسكن

>

grinding 2ccrushing mill design

مسكن

>

grinding 2ccrushing mill design

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

grinding 2ccrushing mill design

Grinding Mill DesignBall Mill Manufacturer

2017220The grinding charge in a rod mill consists of straight steel rods with an initial diameter of 50-100 mm. The length of the rods is

How grinding mill design changed over the last 30 years

202063As grinding mills operate around the clock, losses of revenue due to mechanical failures are unrecoverable. The design of

SAG Mill Grinding Circuit Design Mineral Processing

Semi Autogenous Design FactorsSag Mill Operation ExampleProcess Plant DescriptionSag Mill Design and SpecificationOperating Problems Since CommissioningDesign Changes and Future Operating Strategies

The cyanidation plant consists of a primary crushing plant, a semi-autogenous grinding circuit, agitation leaching circuit, cyclone wash circuit, gold recovery circuit and carbon regeneration circuit. The grinding circuit comprises one 8530 mm diameter x 3650 mm semi-autogenous mill driven by a 3954 kW variable speed dc motor, and one 5030 mm diame...

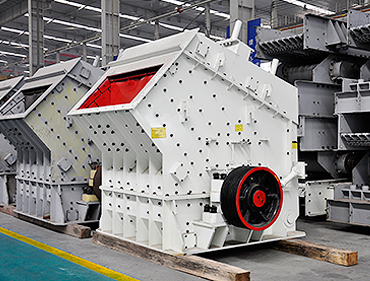

How it Works: Crushers, Grinding Mills and Pulverizers

201762Grinding mills and pulverizers are the second level of material reduction equipment after crushers. Mills and pulverizers

Design and Evaluation of Crushing Hammer mill

201911Abstract and Figures A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design “ANSYS” software.

(PDF) Design of Three-chamber Ball Mill ResearchGate

202111In this , the design method of three chamber ball mill is introduced. Comchambered with the design of Φ 3.5 × 13m three-chamber ball mill, the design

AMIT 135: Lesson 5 Crushing Mining Mill Operator

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to

The Best Homebrew Malts Mills For Crushing Grain [2023]

2022411The Malt Muncher 3 is another great three-roller grain mill at a lower price point than the Monster Brewing Hardware option. This mill might not have the same build quality as the Monster MM3 but the

Grinding Mill Design Crusher Mills, Cone Crusher, Jaw Crushers

We design and develop hammer mills in different sizes to ensure excellent crushing efficiency in diverse applications. Ball Mill Design Highlights Design Highlights : 1) Mill

Design and Evaluation of Crushing Hammer mill

201911A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design “ANSYS” software. Suitability of

How grinding mill design changed over the last 30

202063The design process has changed dramatically with computers though. A typical FEA of a grinding mill that would take about 3 hours on a minicomputer in the late 80’s takes about 3 minutes on a

AG AutogenousSAG Semi-Autogenous Mill

2018417Firstly, conventional crushing and grinding circuits can be designed confidently on the basis of small-scale batch or locked-cycle tests requiring only 35 kg sample per test.

(PDF) DESIGN AND EVALUATE OF A SMALL

20151218Schematic of design hammer mill 1-Main frame ,2-Single phase Electrical motor 1 k Watt, 3-Hammer mill housing The crushing and grinding pro ce ss. is achieved by the use of a set of

Analyzing the Operation and Design of an Autogenous Mill Using

2020129A mill is a device that breaks solid materials into smaller pieces by grinding and crushing. Comminution is an important unit operation in many processes and there are many different types of mills for different types of materials processed. Tega Industries has more than 500 grinding mills lined in over 68 countries globally.

Ball Mill Design/Power Calculation Mineral

2015619The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15

Comparison of Ore Hardness Measurements for Grinding

2021114Grinding Mill Design for the Tenke Project John Starkey1, Principal Consulting Engineer David Meadows2, Manager Mineral Processing Development 1 StarkeyAssociates 344-115 George St. Oakville, ON L6J 0A2 PH: (416) 735-7512 E-mail: john.starkey@sagdesign 2 Phelps Dodge Corporation One North Central Ave.

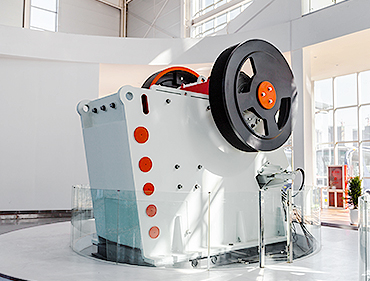

Introduction TO SIZE Reduction Equipments Introduction UNIT

Jaw Crusher can be used in mining, metallurgical industry, construction, road and railway building, chemistry etc. Simple structure easy maintenance. Stable performance. Even final particles and high crushing ratio. FLUID ENERGY MILL. Fluid energy mill is also known as pulverizers. It is used for fine grinding and close particle size control.

Mining and processing plant engineering design

ESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual technical solutions, etc.

Industrial Pin Mill Turbo Mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products . Common

Grinding Metso Outotec

With over a century of experience, Metso Outotec designs and manufactures the most comprehensive line of grinding mills and entire grinding systems for mining companies around the world. The comprehensive offering provides reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operations.

Selection oof Comminution Circuits for Improved Efficiency

• three stage crush, two stage ball mill, e.g. Marvel Loch Gold Mine. • two stage crush, two stage ball mill, e.g. Bronzewing Gold Mine (Lane et al, 1997). • three stage crush, ball mill e.g. (Three Mile Hill). • two stage crush, ball mill, e.g. Pajingo. • a crushing circuit including high pressure grinding rolls (HPGR) at Argyle

sbm/sbm design crushing mill machine.md at main

sbm / sbm design crushing mill machine.md Go to file Go to file T; Go to line L; Copy path Copy permalink; This commit does not belong to any branch on this repository, and may belong to a fork outside of the repository. Cannot retrieve contributors at this time. 51 lines (26 sloc) 28.2 KB

High Pressure Grinding Roll for advanced crushing

Pebble Crushing. Our HPGR is great at de-bottlenecking your problematic pebble circuit. You know how easy it is for hard pebbles to get caught in circulation, small enough to escape the mills but too large to make it

How grinding mill design changed over the last 30

202063The design process has changed dramatically with computers though. A typical FEA of a grinding mill that would take about 3 hours on a minicomputer in the late 80’s takes about 3 minutes on a

(PDF) DESIGN AND EVALUATE OF A SMALL

20151218Schematic of design hammer mill 1-Main frame ,2-Single phase Electrical motor 1 k Watt, 3-Hammer mill housing The crushing and grinding pro ce ss. is achieved by the use of a set of

AG AutogenousSAG Semi-Autogenous Mill

2018417Firstly, conventional crushing and grinding circuits can be designed confidently on the basis of small-scale batch or locked-cycle tests requiring only 35 kg sample per test.

Analyzing the Operation and Design of an Autogenous Mill Using

2020129A mill is a device that breaks solid materials into smaller pieces by grinding and crushing. Comminution is an important unit operation in many processes and there are many different types of mills for different types of materials processed. Tega Industries has more than 500 grinding mills lined in over 68 countries globally.

(PDF) Design, construction and performance

2018719The detailed design procedure for a hammer mill machine is presented. and sorghum in respective sieve sizes for the grinding time and crushing efficiency was within the range of acceptable

Comparison of Ore Hardness Measurements for Grinding

2021114Grinding Mill Design for the Tenke Project John Starkey1, Principal Consulting Engineer David Meadows2, Manager Mineral Processing Development 1 StarkeyAssociates 344-115 George St. Oakville, ON L6J 0A2 PH: (416) 735-7512 E-mail: john.starkey@sagdesign 2 Phelps Dodge Corporation One North Central Ave.

Ball Mill Design/Power Calculation Mineral

2015619The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15

Industrial Pin Mill Turbo Mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products . Common

Introduction TO SIZE Reduction Equipments Introduction UNIT

Jaw Crusher can be used in mining, metallurgical industry, construction, road and railway building, chemistry etc. Simple structure easy maintenance. Stable performance. Even final particles and high crushing ratio. FLUID ENERGY MILL. Fluid energy mill is also known as pulverizers. It is used for fine grinding and close particle size control.

Mining and processing plant engineering design

ESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual technical solutions, etc.

How it Works: Crushers, Grinding Mills and Pulverizers

201762Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

Selection oof Comminution Circuits for Improved Efficiency

• three stage crush, two stage ball mill, e.g. Marvel Loch Gold Mine. • two stage crush, two stage ball mill, e.g. Bronzewing Gold Mine (Lane et al, 1997). • three stage crush, ball mill e.g. (Three Mile Hill). • two stage crush, ball mill, e.g. Pajingo. • a crushing circuit including high pressure grinding rolls (HPGR) at Argyle

sbm/sbm design crushing mill machine.md at main

sbm / sbm design crushing mill machine.md Go to file Go to file T; Go to line L; Copy path Copy permalink; This commit does not belong to any branch on this repository, and may belong to a fork outside of the repository. Cannot retrieve contributors at this time. 51 lines (26 sloc) 28.2 KB

Eco-efficient and cost-effective process design for magnetite iron

2015224Option 1. PC/AGC/RMS/PM/CMS. Primary crushing AG milling in closed circuit with hydrocyclones and pebble crushing rougher magnetic separation pebble milling cleaner magnetic separation. Option 1 resembles the well-known fully autogenous LKAB and Cleveland Cliffs style, low operating cost operations.