مسكن

>

some knowledge about quarryingsome special crusher

مسكن

>

some knowledge about quarryingsome special crusher

منتج

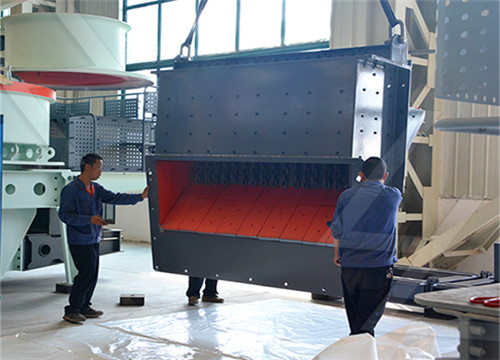

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

some knowledge about quarryingsome special crusher

Selecting the Right Crusher for Quarry Operations Agg-Net

Sean Donaghy, national sales manager of IROCK Crushers discusses what needs to be considered when choosing a crusher. Crushing rock is an age-old idea, but the reality of

5 Types Of Stone Crushers Application and MaintenanceRock Crushing Rule of Thumb Mineral ProcessingMetalCrushing Plant FlowsheetDesign-Layout Mineral ProcUnderstanding the Different Types of Crushers Agg-NetDifferent types of crushers for distinctive needs Metso Out•

Different types of crushers for distinctive needs Metso Outotec

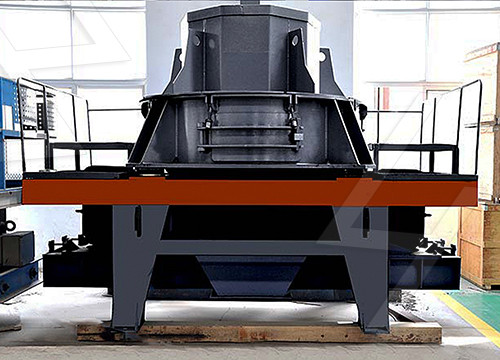

20201217Cone crushers resemble gyratory crushers from the technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary,

:8

7 Types of Stone Crusher and How to Choose the Best?

2021923Advantages: large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable operation, low failure rate, and not easy to be

Used Stone Crusher for sale. Gator equipmentmore MaMobile Crusher Eastman Rock Crusher•

Tips to maximize crushing efficiency PitQuarry

2019513Efficiency can be defined by the ratio of a machine’s work to the energy supplied to the machine. To apply what this means to your crusher, operations produce

:10

Downstream Crushing Options for Secondary, Tertiary

Types of Secondary CrushersTypes of Tertiary and Quaternary CrushersChoosing The Right Secondary Crusher

Secondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crushermay be applied as a secondary crusher. Cone Crushers Cone Crushersare compression-type crushers, which reduce material as it advances dmclanahan

Safe and sound: Crusher safety : PitQuarry

2015714After 20 years of climbing into quarries, I still keep my head on a swivel.” New equipment and technologies have emerged to minimize some of the dangers

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher. Jun 13, 2017Crushing Report 2017 Cost per ton and safety are king for aggregate producers. June 13, 2017 adding

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher Crusher Star Trek 2017/02/24 Starfleet Career Summary 2364 Took up residence aboard U.S.S. Enterprise-D under

some knowledge about quarryingsome special crusher

Star Trek The Next Generation Netflix. Star Trek The Next Generation 1987 TV PG 7 Seasons TV Action Adventure After dropping off some colonists in a nearby system the

Types of Crushers: What You Need to Know Machinery Partner

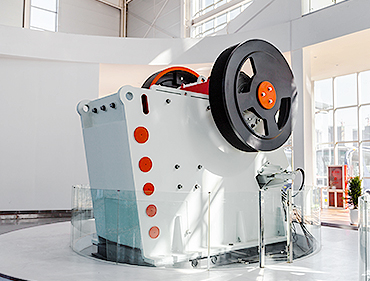

The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries. Through Thomas A.

Crusher an overview ScienceDirect Topics

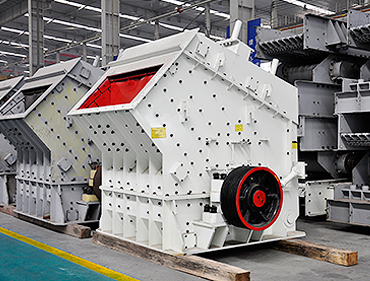

Impact crushers are widely used in stone quarrying industry for making chips as road and building material. These crushers are normally employed for secondary or tertiary crushing. Sign in to download full-size image Figure 13.15. Schematic diagram showing the basic elements and function of an impact crusher. 13.3.1.3 Tertiary Crusher

What Type of Crusher Is Best for Primary Crushing?

2021325Roll Crushers are compression-type machines, so output gradation is controlled mainly through the gap setting between the rolls. A wider setting results in a coarser product. A wider setting also provides greater throughput. Single Roll Crushers feature a low-speed crushing roll that crushes material against a curved crushing plate.

What is a Jaw Crusher? MEKA Crushing Equipment

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.) Obtaining the size or surface area required for the enrichment stage. In general, crushing is carried out in

Safety Consideration in the Development of Improved Stone

stone crusher industry sector could be divided in three categories small, medium and large. The typical characteristics of each category of stone crushers are briefly discussed below Small size stone crushers Typically the stone crushers with a production capacity ranging from 3 to 25 Tonnes Per Hour

Types of Crushers Mineral ProcessingMetallurgy

2015623Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented

Environmental GUIDELINE ON STONE CRUSHING plant

Jets of water to be provided at the mouth of the crushers to ensure that the stones are thoroughly wet during the crushing. The premises and access roads should be kept clean and free of dust at all times. Monitoring of dust emissions, notably particulate matter (PM10), should be carried out on a regular basis. 5.2 Noise abatement

Asphalt Crusher RUBBLE MASTER

The largest Danish demolition company specialises in the crushing and reuse of construction materials directly on site. “With the combination of the RM 100GO! and MS100GO! screen we can recycle 700 m3 of asphalt to 0-16 mm aggregate in a single pass on a daily basis. Economy and efficiency were the key criteria.

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher Crusher Star Trek 2017/02/24 Starfleet Career Summary 2364 Took up residence aboard U.S.S. Enterprise-D under guardianship of mother, CMO Dr. Beverly Crusher.After playing key roles in saving Enterprise from recently collapsed star and helping the "Traveler" return Enterprise to

What are the special abilities of Wesley Crusher?

The Traveler described Wesley Crusher as: a genius with the intricacies of time, energy and propulsion and that those talents needed to be encouraged. It was also stated: he had a unique intelligence and great potential if provided encouragement and opportunity, comparing him to a child prodigy like Mozart.

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher. Jun 13, 2017Crushing Report 2017 Cost per ton and safety are king for aggregate producers. June 13, 2017 adding that anyone who has invested in training on his company's standard crusher can carry that knowledge over to their hybrid model.

What to Do about Lumps: Selecting Crushers and Lump Breakers

2012424Selecting a crusher can be a two-part process. First, consider your application parameters, and then conduct crusher tests on your material. Some parameters about your application to consider are: material characteristics, your final product specification, and how you want to impact the downstream process.

Crushing of coal and calculation of size reduction efficiency.

2015225The first step of Mineral Processing is the Crushing of minerals. This presentation is about crushing of coal and how to calculate the crushing efficiency of coal from processing point of view. Crushing efficiency has been defined in the literature from the power consumption point of view.

Top safety tips for working around crushing and screening equipment

2020612The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to Metso technical training instructor John Starck. Speaking during a recent webinar hosted by the company, Starck pointed out that of 14 fatalities that occurred in

problems associated with stone quarrying on abakaliki

Eco-Friendly Stone quarrying Some issues Abstract Quarrying in a National Park. Apr 20, 2008 rock is then taken to a crusher where it is broken down into smaller pieces What can be done to reduce the problems associated with quarrying? 1. Are there any safety concerns associated with living near a Quarry?

Roll Crushers McLanahan

Why McLanahan Roll Crushers. Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers. The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our

11.19.1 Sand And Gravel Processing US EPA

some deposits, blasting is required to loosen the material prior to processing. The material may undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled.

Safety Consideration in the Development of Improved Stone

stone crusher industry sector could be divided in three categories small, medium and large. The typical characteristics of each category of stone crushers are briefly discussed below Small size stone crushers Typically the stone crushers with a production capacity ranging from 3 to 25 Tonnes Per Hour

4 Types of Stone Crushers' Maintenance and Efficient Improvement

2023215Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures medium-hard or hard rocks like pebble, quartz, granite, etc. It is easy to get premature crusher failure, if operators cannot make a correct and timely inspection and maintenance. 6 Tips to help you prolong the concrusher's service life:

Top safety tips for working around crushing and screening equipment

2020612The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to Metso technical training instructor John Starck. Speaking during a recent webinar hosted by the company, Starck pointed out that of 14 fatalities that occurred in

Types of Crushers Mineral ProcessingMetallurgy

2015623Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented

Environmental GUIDELINE ON STONE CRUSHING plant

Jets of water to be provided at the mouth of the crushers to ensure that the stones are thoroughly wet during the crushing. The premises and access roads should be kept clean and free of dust at all times. Monitoring of dust emissions, notably particulate matter (PM10), should be carried out on a regular basis. 5.2 Noise abatement

What to Do about Lumps: Selecting Crushers and Lump Breakers

2012424Selecting a crusher can be a two-part process. First, consider your application parameters, and then conduct crusher tests on your material. Some parameters about your application to consider are: material characteristics, your final product specification, and how you want to impact the downstream process.

Asphalt Crusher RUBBLE MASTER

The largest Danish demolition company specialises in the crushing and reuse of construction materials directly on site. “With the combination of the RM 100GO! and MS100GO! screen we can recycle 700 m3 of asphalt to 0-16 mm aggregate in a single pass on a daily basis. Economy and efficiency were the key criteria.

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher Crusher Star Trek 2017/02/24 Starfleet Career Summary 2364 Took up residence aboard U.S.S. Enterprise-D under guardianship of mother, CMO Dr. Beverly Crusher.After playing key roles in saving Enterprise from recently collapsed star and helping the "Traveler" return Enterprise to

What Type of Crusher Is Best for Primary Crushing?

2021325Roll Crushers are compression-type machines, so output gradation is controlled mainly through the gap setting between the rolls. A wider setting results in a coarser product. A wider setting also provides greater throughput. Single Roll Crushers feature a low-speed crushing roll that crushes material against a curved crushing plate.

Crushing of coal and calculation of size reduction efficiency.

2015225The first commercial rotary Crusher was patented by Charles Brown, of Gates Iron Works, Chicago in 1878 2/25/2015 6:58:05 AM 13 14. Gates’ Gyratory Crusher 2/25/2015 6:58:05 AM 14 15. Single Roll Crushers • Single Roll Crushers for Stone were developed for crushing Sticky or Muddy materials which could not be handles in Jaw

5 Best Can Crushers Mar. 2023 BestReviews

This solid and economical can crusher can be used indoors or outdoors. Fits cans sizes 12 to 16 ounces. Saves space in recycling by decreasing can size but as much as 80%. Simple to install on indoor or outdoor surfaces. Requires lubricant for most efficient use. Basic Industries International THE CRUSHER Aluminum Can Compactor Check Price

Correct backfill material runner crush or crushed stone

202078The only way to lower the water table is with proper drainage. The best structural material to use for drainage is 3/4 clean crushed stone. Using all clean crushed stone as backfill can invite "surface" water down to the sides and bottom of your pool. That is why it is imperative to have a perforated pipe at the lowest point of any stone

Different types of crushers for distinctive needs Metso Outotec

20201217Cone crushers resemble gyratory crushers from the technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary,

7 Types of Stone Crusher and How to Choose the Best?

2021923Advantages: large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable operation, low failure rate, and not easy to be

Tips to maximize crushing efficiency PitQuarry

2019513Efficiency can be defined by the ratio of a machine’s work to the energy supplied to the machine. To apply what this means to your crusher, operations produce

Downstream Crushing Options for Secondary, Tertiary

Types of Secondary CrushersTypes of Tertiary and Quaternary CrushersChoosing The Right Secondary Crusher

Secondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crushermay be applied as a secondary crusher. Cone Crushers Cone Crushersare compression-type crushers, which reduce material as it advances dmclanahan

Safe and sound: Crusher safety : PitQuarry

2015714After 20 years of climbing into quarries, I still keep my head on a swivel.” New equipment and technologies have emerged to minimize some of the dangers

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher. Jun 13, 2017Crushing Report 2017 Cost per ton and safety are king for aggregate producers. June 13, 2017 adding

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher Crusher Star Trek 2017/02/24 Starfleet Career Summary 2364 Took up residence aboard U.S.S. Enterprise-D under

some knowledge about quarryingsome special crusher

Star Trek The Next Generation Netflix. Star Trek The Next Generation 1987 TV PG 7 Seasons TV Action Adventure After dropping off some colonists in a nearby system the

Types of Crushers: What You Need to Know Machinery Partner

The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries. Through Thomas A.

Crusher an overview ScienceDirect Topics

Impact crushers are widely used in stone quarrying industry for making chips as road and building material. These crushers are normally employed for secondary or tertiary crushing. Sign in to download full-size image Figure 13.15. Schematic diagram showing the basic elements and function of an impact crusher. 13.3.1.3 Tertiary Crusher

What Type of Crusher Is Best for Primary Crushing?

2021325Roll Crushers are compression-type machines, so output gradation is controlled mainly through the gap setting between the rolls. A wider setting results in a coarser product. A wider setting also provides greater throughput. Single Roll Crushers feature a low-speed crushing roll that crushes material against a curved crushing plate.

What is a Jaw Crusher? MEKA Crushing Equipment

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.) Obtaining the size or surface area required for the enrichment stage. In general, crushing is carried out in

Safety Consideration in the Development of Improved Stone

stone crusher industry sector could be divided in three categories small, medium and large. The typical characteristics of each category of stone crushers are briefly discussed below Small size stone crushers Typically the stone crushers with a production capacity ranging from 3 to 25 Tonnes Per Hour

Types of Crushers Mineral ProcessingMetallurgy

2015623Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented

Environmental GUIDELINE ON STONE CRUSHING plant

Jets of water to be provided at the mouth of the crushers to ensure that the stones are thoroughly wet during the crushing. The premises and access roads should be kept clean and free of dust at all times. Monitoring of dust emissions, notably particulate matter (PM10), should be carried out on a regular basis. 5.2 Noise abatement

Asphalt Crusher RUBBLE MASTER

The largest Danish demolition company specialises in the crushing and reuse of construction materials directly on site. “With the combination of the RM 100GO! and MS100GO! screen we can recycle 700 m3 of asphalt to 0-16 mm aggregate in a single pass on a daily basis. Economy and efficiency were the key criteria.

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher Crusher Star Trek 2017/02/24 Starfleet Career Summary 2364 Took up residence aboard U.S.S. Enterprise-D under guardianship of mother, CMO Dr. Beverly Crusher.After playing key roles in saving Enterprise from recently collapsed star and helping the "Traveler" return Enterprise to

What are the special abilities of Wesley Crusher?

The Traveler described Wesley Crusher as: a genius with the intricacies of time, energy and propulsion and that those talents needed to be encouraged. It was also stated: he had a unique intelligence and great potential if provided encouragement and opportunity, comparing him to a child prodigy like Mozart.

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher. Jun 13, 2017Crushing Report 2017 Cost per ton and safety are king for aggregate producers. June 13, 2017 adding that anyone who has invested in training on his company's standard crusher can carry that knowledge over to their hybrid model.

What to Do about Lumps: Selecting Crushers and Lump Breakers

2012424Selecting a crusher can be a two-part process. First, consider your application parameters, and then conduct crusher tests on your material. Some parameters about your application to consider are: material characteristics, your final product specification, and how you want to impact the downstream process.

Crushing of coal and calculation of size reduction efficiency.

2015225The first step of Mineral Processing is the Crushing of minerals. This presentation is about crushing of coal and how to calculate the crushing efficiency of coal from processing point of view. Crushing efficiency has been defined in the literature from the power consumption point of view.

Top safety tips for working around crushing and screening equipment

2020612The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to Metso technical training instructor John Starck. Speaking during a recent webinar hosted by the company, Starck pointed out that of 14 fatalities that occurred in

problems associated with stone quarrying on abakaliki

Eco-Friendly Stone quarrying Some issues Abstract Quarrying in a National Park. Apr 20, 2008 rock is then taken to a crusher where it is broken down into smaller pieces What can be done to reduce the problems associated with quarrying? 1. Are there any safety concerns associated with living near a Quarry?

Roll Crushers McLanahan

Why McLanahan Roll Crushers. Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers. The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our

11.19.1 Sand And Gravel Processing US EPA

some deposits, blasting is required to loosen the material prior to processing. The material may undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled.

Safety Consideration in the Development of Improved Stone

stone crusher industry sector could be divided in three categories small, medium and large. The typical characteristics of each category of stone crushers are briefly discussed below Small size stone crushers Typically the stone crushers with a production capacity ranging from 3 to 25 Tonnes Per Hour

4 Types of Stone Crushers' Maintenance and Efficient Improvement

2023215Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures medium-hard or hard rocks like pebble, quartz, granite, etc. It is easy to get premature crusher failure, if operators cannot make a correct and timely inspection and maintenance. 6 Tips to help you prolong the concrusher's service life:

Top safety tips for working around crushing and screening equipment

2020612The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to Metso technical training instructor John Starck. Speaking during a recent webinar hosted by the company, Starck pointed out that of 14 fatalities that occurred in

Types of Crushers Mineral ProcessingMetallurgy

2015623Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented

Environmental GUIDELINE ON STONE CRUSHING plant

Jets of water to be provided at the mouth of the crushers to ensure that the stones are thoroughly wet during the crushing. The premises and access roads should be kept clean and free of dust at all times. Monitoring of dust emissions, notably particulate matter (PM10), should be carried out on a regular basis. 5.2 Noise abatement

What to Do about Lumps: Selecting Crushers and Lump Breakers

2012424Selecting a crusher can be a two-part process. First, consider your application parameters, and then conduct crusher tests on your material. Some parameters about your application to consider are: material characteristics, your final product specification, and how you want to impact the downstream process.

Asphalt Crusher RUBBLE MASTER

The largest Danish demolition company specialises in the crushing and reuse of construction materials directly on site. “With the combination of the RM 100GO! and MS100GO! screen we can recycle 700 m3 of asphalt to 0-16 mm aggregate in a single pass on a daily basis. Economy and efficiency were the key criteria.

some knowledge about quarryingsome special crusher

some knowledge about quarryingsome special crusher Crusher Star Trek 2017/02/24 Starfleet Career Summary 2364 Took up residence aboard U.S.S. Enterprise-D under guardianship of mother, CMO Dr. Beverly Crusher.After playing key roles in saving Enterprise from recently collapsed star and helping the "Traveler" return Enterprise to

What Type of Crusher Is Best for Primary Crushing?

2021325Roll Crushers are compression-type machines, so output gradation is controlled mainly through the gap setting between the rolls. A wider setting results in a coarser product. A wider setting also provides greater throughput. Single Roll Crushers feature a low-speed crushing roll that crushes material against a curved crushing plate.

Crushing of coal and calculation of size reduction efficiency.

2015225The first commercial rotary Crusher was patented by Charles Brown, of Gates Iron Works, Chicago in 1878 2/25/2015 6:58:05 AM 13 14. Gates’ Gyratory Crusher 2/25/2015 6:58:05 AM 14 15. Single Roll Crushers • Single Roll Crushers for Stone were developed for crushing Sticky or Muddy materials which could not be handles in Jaw

5 Best Can Crushers Mar. 2023 BestReviews

This solid and economical can crusher can be used indoors or outdoors. Fits cans sizes 12 to 16 ounces. Saves space in recycling by decreasing can size but as much as 80%. Simple to install on indoor or outdoor surfaces. Requires lubricant for most efficient use. Basic Industries International THE CRUSHER Aluminum Can Compactor Check Price

Correct backfill material runner crush or crushed stone

202078The only way to lower the water table is with proper drainage. The best structural material to use for drainage is 3/4 clean crushed stone. Using all clean crushed stone as backfill can invite "surface" water down to the sides and bottom of your pool. That is why it is imperative to have a perforated pipe at the lowest point of any stone