مسكن

>

Gold Processing Plant Malaysiasand Production Equipment

مسكن

>

Gold Processing Plant Malaysiasand Production Equipment

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Gold Processing Plant Malaysiasand Production Equipment

Gold Ore ProcessingHandling Equipment FEECO

•

Rock Gold Gravity Processing Plant Hengcheng Mining

Above rock gold processing plant design could have effectively recover >70% of gold. And the tailing material could be stocked up for future

Gold Processing Equipment, Process Flow, Cases JXSC

•

Gold processing 101 Mining Magazine

201797At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and

Gold Processing Plant, Equipment Mineral Processing

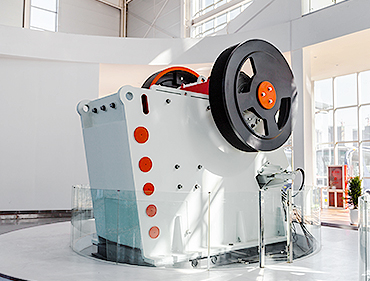

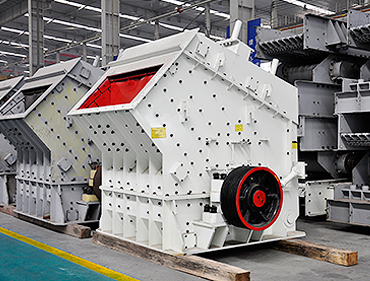

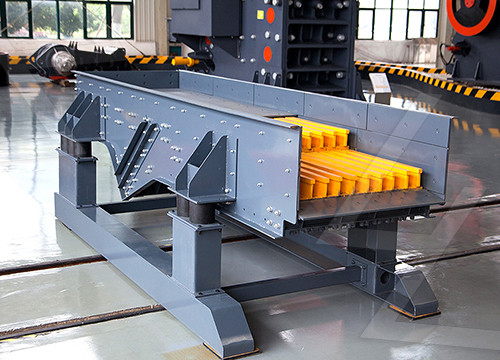

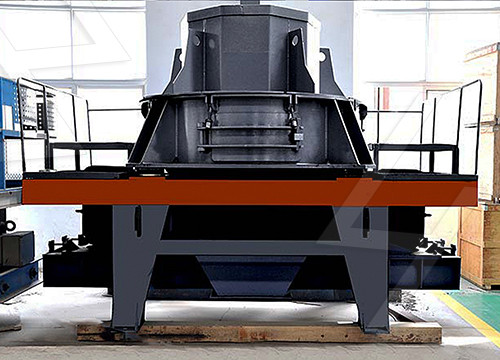

20221122Gold processing plant common including washingscreening, crushinggrinding, beneficiation, concentrate and drying. 1. Washingscreening: It is mainly to remove the mud in the placer gold

Gold Processing Plant Prominer (Shanghai) Mining

Prominer supplies customized solution for different types of gold ore. General processing technologies for gold ore are summarized as below: I. Physical Gold processing technology: Crushing&Grinding Gravity

Used Gold Processing Plants for sale. equipmentmore

40 TPD gold plant with crush, grind, gravity, and processing circuits USED 40 ton per day gold processing plant with mill. Operational when shut down. CRUSH: Jaw crusher:

Gold Process Equipment JXSC Mineral

JXSC has very strict production management and advanced production technology in Gold Processing Equipment. We own advanced cutting, automatic welding, and boring

Operating Costs of Gold Processing Plant Mineral

2016318The EXAMPLE Gold Mine Operating Manual has been prepared to provide a practical reference for operators in the EXAMPLE Gold Mines Processing Plant. This manual contains basic information

Gold Processing PlantsComplete Ore Process Plant

Mineral Processing Plants Gold, Silver, Copper, Zinc, Lead, etc, Ore NO Chemical Gravity Gold Recovery Equipment Gravity GoldFlotation Plant Polymetallic Flotation Concentrator Monometallic Flotation Process

Gold Refining Plant Metso Outotec

The Metso Outotec Gold Refining Plant is the result of more than 30 years’ experience in developing robust and cost-effective solutions for precious metals recovery and refining. The process has been

Gold processing 101 Mining Magazine

201797At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 0.5. Clearly this is a function of gold price, but in the current gold

Gold processing Britannica

The gold was concentrated by washing away the lighter river sands with water, leaving behind the dense gold particles, which could then be further concentrated by melting. By 2000 bc the process of purifying gold-silver

Operating Costs of Gold Processing Plant Mineral

2016318The savings made in lower operation costs and lower maintenance costs are noticeable and this saving was also made in the face of a 12.5% increase in wages made when the new plant was started.

Gold Processing PlantsComplete Ore Process

The chart/table below are crude budgetary estimations for the cost of major plant equipment. Actual cost will vary depending of the process details and detailed equipment list and origin. Please use this to decide if your

Gold Process Equipment JXSC Mineral

JXSC has very strict production management and advanced production technology in Gold Processing Equipment. We own advanced cutting, automatic welding, and boring machine, which make our gold mining machine of high quality and good appearance. JXSC has been engaged in the production and sales of gold process equipment since 1985.

Used Gold Processing Plants for sale. equipment

40 TPD gold plant with crush, grind, gravity, and processing circuits USED 40 ton per day gold processing plant with mill. Operational when shut down. CRUSH: Jaw crusher: 7x10 in with 15 HP Pennsylvania ammermill: 15 HP 3x6 ft double deck screen with 5 HP Conveyors for feed an USA Trusted Seller

Mineral Processing Equipment Multotec

For over 50 years, Multotec has focussed on supplying process technology solutions aimed at reducing the operating costs of mineral processing plants.. Driven by a global team of process engineers and metallurgical

Alluvial gold processing plant gold wash plant

Alluvial is a term that refers to soil sediments and the various sand, silt, gravel, clay or other deposited matter left behind by flowing water. “Alluvial gold” refers to the type of gold dust found in that kind of soil. When the

How Does A CIP Gold Processing Plant Work?

2021318The main process of the CIP gold processing plant to extract gold from ore and convert it into pure metal can be divided into 6 steps: crushing, screening, grinding, classification, carbon slurry gold

Dono Holong Senior Supervisor/Trainer Gold

Senior Supervisor/Trainer Gold Room. An open pit mine. The processing plant facilities comprises 1 x Jaw Crusher, 1 x SAG Mill, 1 x Ball Mill, 1 x

Production of Gold West Virginia University

of high-grade ore per year for 8 years. The deposit contains 0.12 ounces of gold per ton of high-grade ore and can be acquired at a cost of $10 per ton of ore (cost of mining ore at site). A sodium cyanide process is used to extract the gold from the ore, and various other processing techniques are used to produce 99.9% pure gold bullion from

Modular Gold Plants Proprietary Resources Gold

Modular Gold Plants (MGP) by Resources Gold Technology are complete turnkey modular gold plants designed for the 200 to 600 ton per day producer. The flotation circuit includes rougher recovery, scavenging

EXPLORER Portable Plants 2-1000 TPH Portable Wash Plants

The EXPLORER ® Portable Processing Plants are Portable Wash Plants exclusively designed, patented and developed by DOVE, for surface mining of alluvial (placer) Gold, Diamonds, color Gemstones, Base metals and Ferrous metals.. VARIOUS CONFIGURATIONS BASED ON YOUR REQUIREMENTS: EXPLORER ® Portable

Gold Processing Plant Multotec

Wherever your operation may be, whatever your processing requirements, Multotec will help ensure your gold processing plant is optimised to deliver the lowest cost per ton. We offer a wide range of ore processing

Gold Refining Plant Metso Outotec

The Metso Outotec Gold Refining Plant is the result of more than 30 years’ experience in developing robust and cost-effective solutions for precious metals recovery and refining. The process has been

Gold Processing Plant, Equipment Mineral

Gold processing plant common including washingscreening, crushinggrinding, beneficiation, concentrate and drying.. 1. Washingscreening: It is mainly to remove the mud in the placer gold ore, or to make the

Used Gold Processing Plants for sale. equipment

Rotary Scrubber-Screen for Gold, LeadPrecious Minerals Recovery. USED. (1) one Portable 6’ 4” diameter x 37’ long Duel Drum Rotary Scrubber-Screen for Gold, LeadPrecious Minerals Recovery, 30 h.p. vary-speed rubber tire drive, CAT track roller supports, duel drum design, OUTE $49,850 USD.

Operating Costs of Gold Processing Plant Mineral

2016318The savings made in lower operation costs and lower maintenance costs are noticeable and this saving was also made in the face of a 12.5% increase in wages made when the new plant was started.

Mineral Processing Equipment Multotec

For over 50 years, Multotec has focussed on supplying process technology solutions aimed at reducing the operating costs of mineral processing plants.. Driven by a global team of process engineers and metallurgical

Gold Mining Equipment Gold Mining Wash Plant

The introduction of the CDE washing equipment in your gold mining process incorporates hydrocyclone technology and can be employed on gold mining operations to remove the very fine minus 75 micron / 200

Cyanide-free gold recovery CSIRO

The infrastructure for a processing plant that uses cyanidation typically costs $30 million, and is therefore, a barrier to entry for gold miners with smaller deposits that do not fit into the large-scale economies of gold

Alluvial gold processing plant gold wash plant

Alluvial is a term that refers to soil sediments and the various sand, silt, gravel, clay or other deposited matter left behind by flowing water. “Alluvial gold” refers to the type of gold dust found in that kind of soil. When the

Dono Holong Senior Supervisor/Trainer Gold

Senior Supervisor/Trainer Gold Room. An open pit mine. The processing plant facilities comprises 1 x Jaw Crusher, 1 x SAG Mill, 1 x Ball Mill, 1 x

Gold Mining Equipment 911Metallurgist

Since most of the information online provides lists of gold mining equipment for amateur level mining with equipment like gold pans, metal detectors, mini sluice box, blue bowl, geologist rock pick, soil scoop,

Gold processing Britannica

gold processing, preparation of the ore for use in various products. For thousands of years the word gold has connoted something of beauty or value. These images are derived from two properties of gold, its colour and its chemical stability. The colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with

Development of underground gold processing plants

201011T.J. Daffern. Underground gold processing plants have potential advantages over traditional surface installations related to a smaller environmental footprint, reduced capital and mining costs

EXPLORER Portable Plants 2-1000 TPH Portable Wash Plants

The EXPLORER ® Portable Processing Plants are Portable Wash Plants exclusively designed, patented and developed by DOVE, for surface mining of alluvial (placer) Gold, Diamonds, color Gemstones, Base metals and Ferrous metals.. VARIOUS CONFIGURATIONS BASED ON YOUR REQUIREMENTS: EXPLORER ® Portable