مسكن

>

cement mill trunnion repair

مسكن

>

cement mill trunnion repair

منتج

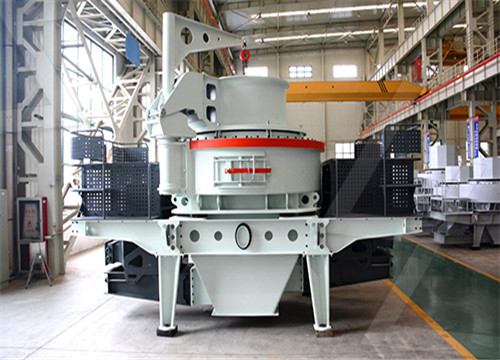

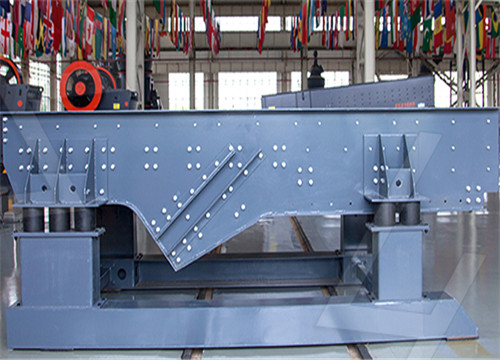

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

cement mill trunnion repair

CementTrunnion Assembly Precision Roll Grinders

PRG offers emergency service as well as fabrication and grinding services for spare or new replacement trunnion assemblies to reduce downtime due to scheduled maintenance or

Ball Mill Trunnion Bearing Installation Lafarge Ndola

20191224Installation of a ball mill. particular emphasis of video is how to install the trunnion bearings, scraping, etc. ideal for total beginners. doesnt go into m...

Trunnion Bearing Assembly Ball MillRod MillBall Mill MaintenanceInstallation Procedure•

BALL MILL TRUNION HEAD CRACK REPAIR adorfon

SOLUTION Detect and repair cracks in mill head, carry out PWHT and run the mill till new mill head arrives. Ador has performance proven welding consumables and Quick

Typical Reason to Replace a Ball Mill Trunnion

20151028It is unclear if the trunnion damage was known ahead of time and planned for a change-out during the shell reline or if it was

:1

Ball mill trunnion replacement

Trunnion 2. Tight-fitting bolt 3. Mill head 4. Trunnion liner 5. Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which

Cement mill Cracks in the mill ends IMIA

The cement mill subject of the loss described in this article is a ball mill and consists of a horizontal cylinder, closed at both ends by heavy cast walls (Fig. 1). In order to feed the

Trunnion Bearing Assembly Ball MillRod Mill

2015728The bushing is bored and scraped to fit the mill trunnion. The bushing is provided with end flanges thus assuring that the trunnion flanges run against a bronze face. On smaller mills rigid or swivel type

Titus Restoration: Polished Concrete Floors and Industrial

Titus Restoration is a concrete polishing contractor and industrial concrete floor repair specialist serving retail, warehouses, and factories nationwide. (888) 569-3914 sales@titusrestoration Home

Lintel StabilizationReplacement EverClearEnterprises

Used to bridge openings in masonry, lintels are a crucial component to the wall’s strength and structural integrity. Over time, the combination of water penetration, leaching of chemicals from adjacent cementitious

How to repair a crack in the trunnion of a ball mill?

2023214Repairing a crack in the trunnion of a ball mill requires some specialized tools and techniques. First, you will need to remove the trunnion from the mill and

Grinding Mill Liners and Wear Parts Columbia Steel Casting Co.,

We offer a full line of parts for rod, ball, and semi-autogenous grinding mills for cement plants. Shell liners We offer many choices in design and alloys for all popular mills, ranging from traditional wave styles to step liners, classifying liners and SAG mill liners. Trunnion liners Not many foundries are capable of making trunnion liners.

Premium spare parts for trunnion-supported mill flsmidth

From mill shells to trunnion liners and everything in between, a trunnion-supported mill works better with more durable, higher performing parts. Our replacements provide premium service to customers, promoting innovative design and increased durability. Enjoy lower costs and less downtime with EXCEL premium trunnion-supported mill parts.

Trunnion Wheel (Roller) Replacement FEECO International Inc.

Determining Whether or Not to Relace a Trunnion Wheel. Using the 5% rule of thumb as a guide, plant managers can usually assess the need for replacement on their own. If the trunnion wheel’s original diameter was 40”, a 5% loss would be 2”, so in measuring the trunnion’s current diameter, anything approaching or less than 38” should

Ball mill trunnion replacement

Trunnion 2. Tight-fitting bolt 3. Mill head 4. Trunnion liner 5. Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which has given us a unique insight into the stresses and strains arising out of ball mill operations. The large alternating stresses placed on ball mill trunnions

Typical Reason to Replace a Ball Mill Trunnion

20151028Wearing through trunnion liner can cause localized erosion/weakness. Lube or operational failure may have caused overheating and/or galling damage of journal surface. Other Typical, and maybe

Trunnion bearing housings for grinding mills FSDR..K series

Trunnion bearing housings for grinding mills FSDR..K series Trunnion bearing housings for grinding mills FSDR..K series FSDR .. K housings are large, low-weight pillow (plummer) block housings designed specifically for grinding mills. They operate under arduous conditions in highly contaminated environments.

Ball Mill MaintenanceInstallation Procedure

20161019Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion bearings. In the case of ball mills, all internal

Ceramic Ball Mill Relining and Refurbishing Paul O.

Repair or Replace Other Components: Mill cylinders Replace portions of a corroded cylinder Repair babbitted bearings Replace Babbitted bearings with roller bearings including machining the trunnions to size Replace

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much

What are the Components of Ball Mill Inside and How to Repair

The material to be ground is fed into the ball mill through a hollow trunnion at the end of the cylinder. The material can be dry or wet, and it can be any type of material, including minerals, ores, chemicals, and others. How to Repair Ball Mill Inside Parts. 85tph Cement Ball Mill Put Into Operation In Indian Cement Plant. Read More

Ball Mill Trunnion Expert Ball Mill Parts Manufacturer

AGICO Ball Mill Trunnion. AGICO CEMENT is a cement equipment manufacturer with strong R&D and manufacturing capacity. Our ball mills and spare parts are widely used in cement, mining, building materials,

Analysis of Raw Mill Machines Maintenance in Cement Industry

2020530The machines used in cement production at the factory include raw mill machines, kiln machines, and cement mill machines. The more often a machine is damaged, the average time between failures of

TrunnionMill Bearing Fluid Anion Specialty Chemicals

TrunnionMill Bearing Fluid Improve High-Temperature Trunnion and Mill Bearing Overloading. We solve trunnion and mill bearing lube problems for people in the chemical, waste, processing, lime, cement and stone industries. We provide expert consulting and field troubleshooting support to help our customers find the best lubricating products.

CHAENG+Ball mill trunnion+Cement industry+The hardness and

Therefore, the ball mill trunnion /ball mill head is required to have good comprehensive mechanical properties in actual production, and there must be no casting defects such as shrinkage, air hole, sand inclusion, etc. Scientific and reasonable process plan can improve the overall quality of the product and improve the production efficiency.

Premium spare parts for trunnion-supported mill flsmidth

From mill shells to trunnion liners and everything in between, a trunnion-supported mill works better with more durable, higher performing parts. Our replacements provide premium service to customers, promoting innovative design and increased durability. Enjoy lower costs and less downtime with EXCEL premium trunnion-supported mill parts.

Trunnion Wheel (Roller) Replacement FEECO International Inc.

Determining Whether or Not to Relace a Trunnion Wheel. Using the 5% rule of thumb as a guide, plant managers can usually assess the need for replacement on their own. If the trunnion wheel’s original diameter was 40”, a 5% loss would be 2”, so in measuring the trunnion’s current diameter, anything approaching or less than 38” should

Ball mill trunnion replacement

Trunnion 2. Tight-fitting bolt 3. Mill head 4. Trunnion liner 5. Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which has given us a unique insight into the stresses and strains arising out of ball mill operations. The large alternating stresses placed on ball mill trunnions

Typical Reason to Replace a Ball Mill Trunnion

20151028Wearing through trunnion liner can cause localized erosion/weakness. Lube or operational failure may have caused overheating and/or galling damage of journal surface. Other Typical, and maybe

Rotary Kiln Maintenance Procedures Anion Specialty Chemicals

loads, and make prioritized repair recommendations. Our reports include trending of variables critical to kiln operations, like shell ovality and tire clearance. This cost-effective preventive maintenance concept significantly improves kiln run time and productivity. All measurements and adjustments are done with the kiln in operation. 4.

Trunnion bearing housings for grinding mills FSDR..K series

Trunnion bearing housings for grinding mills FSDR..K series Trunnion bearing housings for grinding mills FSDR..K series FSDR .. K housings are large, low-weight pillow (plummer) block housings designed specifically for grinding mills. They operate under arduous conditions in highly contaminated environments.

Ball Mill MaintenanceInstallation Procedure

20161019Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion bearings. In the case of ball mills, all internal

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much

Analysis of Raw Mill Machines Maintenance in

2020530The machines used in cement production at the factory include raw mill machines, kiln machines, and cement mill machines. The more often a machine is damaged, the average time between failures of

Ball Mill Trunnion Expert Ball Mill Parts Manufacturer

AGICO Ball Mill Trunnion. AGICO CEMENT is a cement equipment manufacturer with strong R&D and manufacturing capacity. Our ball mills and spare parts are widely used in cement, mining, building materials,

What are the Components of Ball Mill Inside and How to Repair

The material to be ground is fed into the ball mill through a hollow trunnion at the end of the cylinder. The material can be dry or wet, and it can be any type of material, including minerals, ores, chemicals, and others. How to Repair Ball Mill Inside Parts. 85tph Cement Ball Mill Put Into Operation In Indian Cement Plant. Read More

TrunnionMill Bearing Fluid Anion Specialty Chemicals

TrunnionMill Bearing Fluid Improve High-Temperature Trunnion and Mill Bearing Overloading. We solve trunnion and mill bearing lube problems for people in the chemical, waste, processing, lime, cement and stone industries. We provide expert consulting and field troubleshooting support to help our customers find the best lubricating products.

Ball Mill Trunnion Hollow Shaft For Ball Mill Customization

AGICO CEMENT ensures that the heat treatment is evenly heated Advanced technology As a high-quality ball mill trunnion casting enterprise, AGICO CEMENT has a series of quality inspection technologies for steel castings to ensure the quality of steel castings. Strong production capacity

Analysis of the criticality of flaws found in trunnion of grinding

201631Oil lubrication failure on grinding mill trunnion bearings causes thermal stresses in surfaces and cracks at low stress region. • A contact temperature of 150 °C may causes a stress over the yield strength of the trunnion nodular cast iron.. The use of standard BS 7910 on fatigue crack propagation in the trunnion proved to be more

BALL MILL TRUNION HEAD CRACK REPAIR adorfon

SOLUTION Detect and repair cracks in mill head, carry out PWHT and run the mill till new mill head arrives. Ador has performance proven welding consumables and Quick

Typical Reason to Replace a Ball Mill Trunnion

20151028It is unclear if the trunnion damage was known ahead of time and planned for a change-out during the shell reline or if it was

Ball mill trunnion replacement

Trunnion 2. Tight-fitting bolt 3. Mill head 4. Trunnion liner 5. Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which

Cement mill Cracks in the mill ends IMIA

The cement mill subject of the loss described in this article is a ball mill and consists of a horizontal cylinder, closed at both ends by heavy cast walls (Fig. 1). In order to feed the

Trunnion Bearing Assembly Ball MillRod Mill

2015728The bushing is bored and scraped to fit the mill trunnion. The bushing is provided with end flanges thus assuring that the trunnion flanges run against a bronze face. On smaller mills rigid or swivel type

Titus Restoration: Polished Concrete Floors and Industrial

Titus Restoration is a concrete polishing contractor and industrial concrete floor repair specialist serving retail, warehouses, and factories nationwide. (888) 569-3914 sales@titusrestoration Home

Lintel StabilizationReplacement EverClearEnterprises

Used to bridge openings in masonry, lintels are a crucial component to the wall’s strength and structural integrity. Over time, the combination of water penetration, leaching of chemicals from adjacent cementitious

How to repair a crack in the trunnion of a ball mill?

2023214Repairing a crack in the trunnion of a ball mill requires some specialized tools and techniques. First, you will need to remove the trunnion from the mill and

Grinding Mill Liners and Wear Parts Columbia Steel Casting Co.,

We offer a full line of parts for rod, ball, and semi-autogenous grinding mills for cement plants. Shell liners We offer many choices in design and alloys for all popular mills, ranging from traditional wave styles to step liners, classifying liners and SAG mill liners. Trunnion liners Not many foundries are capable of making trunnion liners.

Premium spare parts for trunnion-supported mill flsmidth

From mill shells to trunnion liners and everything in between, a trunnion-supported mill works better with more durable, higher performing parts. Our replacements provide premium service to customers, promoting innovative design and increased durability. Enjoy lower costs and less downtime with EXCEL premium trunnion-supported mill parts.

Trunnion Wheel (Roller) Replacement FEECO International Inc.

Determining Whether or Not to Relace a Trunnion Wheel. Using the 5% rule of thumb as a guide, plant managers can usually assess the need for replacement on their own. If the trunnion wheel’s original diameter was 40”, a 5% loss would be 2”, so in measuring the trunnion’s current diameter, anything approaching or less than 38” should

Ball mill trunnion replacement

Trunnion 2. Tight-fitting bolt 3. Mill head 4. Trunnion liner 5. Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which has given us a unique insight into the stresses and strains arising out of ball mill operations. The large alternating stresses placed on ball mill trunnions

Typical Reason to Replace a Ball Mill Trunnion

20151028Wearing through trunnion liner can cause localized erosion/weakness. Lube or operational failure may have caused overheating and/or galling damage of journal surface. Other Typical, and maybe

Trunnion bearing housings for grinding mills FSDR..K series

Trunnion bearing housings for grinding mills FSDR..K series Trunnion bearing housings for grinding mills FSDR..K series FSDR .. K housings are large, low-weight pillow (plummer) block housings designed specifically for grinding mills. They operate under arduous conditions in highly contaminated environments.

Ball Mill MaintenanceInstallation Procedure

20161019Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion bearings. In the case of ball mills, all internal

Ceramic Ball Mill Relining and Refurbishing Paul O.

Repair or Replace Other Components: Mill cylinders Replace portions of a corroded cylinder Repair babbitted bearings Replace Babbitted bearings with roller bearings including machining the trunnions to size Replace

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much

What are the Components of Ball Mill Inside and How to Repair

The material to be ground is fed into the ball mill through a hollow trunnion at the end of the cylinder. The material can be dry or wet, and it can be any type of material, including minerals, ores, chemicals, and others. How to Repair Ball Mill Inside Parts. 85tph Cement Ball Mill Put Into Operation In Indian Cement Plant. Read More

Ball Mill Trunnion Expert Ball Mill Parts Manufacturer

AGICO Ball Mill Trunnion. AGICO CEMENT is a cement equipment manufacturer with strong R&D and manufacturing capacity. Our ball mills and spare parts are widely used in cement, mining, building materials,

Analysis of Raw Mill Machines Maintenance in Cement Industry

2020530The machines used in cement production at the factory include raw mill machines, kiln machines, and cement mill machines. The more often a machine is damaged, the average time between failures of

TrunnionMill Bearing Fluid Anion Specialty Chemicals

TrunnionMill Bearing Fluid Improve High-Temperature Trunnion and Mill Bearing Overloading. We solve trunnion and mill bearing lube problems for people in the chemical, waste, processing, lime, cement and stone industries. We provide expert consulting and field troubleshooting support to help our customers find the best lubricating products.

CHAENG+Ball mill trunnion+Cement industry+The hardness and

Therefore, the ball mill trunnion /ball mill head is required to have good comprehensive mechanical properties in actual production, and there must be no casting defects such as shrinkage, air hole, sand inclusion, etc. Scientific and reasonable process plan can improve the overall quality of the product and improve the production efficiency.

Premium spare parts for trunnion-supported mill flsmidth

From mill shells to trunnion liners and everything in between, a trunnion-supported mill works better with more durable, higher performing parts. Our replacements provide premium service to customers, promoting innovative design and increased durability. Enjoy lower costs and less downtime with EXCEL premium trunnion-supported mill parts.

Trunnion Wheel (Roller) Replacement FEECO International Inc.

Determining Whether or Not to Relace a Trunnion Wheel. Using the 5% rule of thumb as a guide, plant managers can usually assess the need for replacement on their own. If the trunnion wheel’s original diameter was 40”, a 5% loss would be 2”, so in measuring the trunnion’s current diameter, anything approaching or less than 38” should

Ball mill trunnion replacement

Trunnion 2. Tight-fitting bolt 3. Mill head 4. Trunnion liner 5. Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which has given us a unique insight into the stresses and strains arising out of ball mill operations. The large alternating stresses placed on ball mill trunnions

Typical Reason to Replace a Ball Mill Trunnion

20151028Wearing through trunnion liner can cause localized erosion/weakness. Lube or operational failure may have caused overheating and/or galling damage of journal surface. Other Typical, and maybe

Rotary Kiln Maintenance Procedures Anion Specialty Chemicals

loads, and make prioritized repair recommendations. Our reports include trending of variables critical to kiln operations, like shell ovality and tire clearance. This cost-effective preventive maintenance concept significantly improves kiln run time and productivity. All measurements and adjustments are done with the kiln in operation. 4.

Trunnion bearing housings for grinding mills FSDR..K series

Trunnion bearing housings for grinding mills FSDR..K series Trunnion bearing housings for grinding mills FSDR..K series FSDR .. K housings are large, low-weight pillow (plummer) block housings designed specifically for grinding mills. They operate under arduous conditions in highly contaminated environments.

Ball Mill MaintenanceInstallation Procedure

20161019Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion bearings. In the case of ball mills, all internal

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much

Analysis of Raw Mill Machines Maintenance in

2020530The machines used in cement production at the factory include raw mill machines, kiln machines, and cement mill machines. The more often a machine is damaged, the average time between failures of

Ball Mill Trunnion Expert Ball Mill Parts Manufacturer

AGICO Ball Mill Trunnion. AGICO CEMENT is a cement equipment manufacturer with strong R&D and manufacturing capacity. Our ball mills and spare parts are widely used in cement, mining, building materials,

What are the Components of Ball Mill Inside and How to Repair

The material to be ground is fed into the ball mill through a hollow trunnion at the end of the cylinder. The material can be dry or wet, and it can be any type of material, including minerals, ores, chemicals, and others. How to Repair Ball Mill Inside Parts. 85tph Cement Ball Mill Put Into Operation In Indian Cement Plant. Read More

TrunnionMill Bearing Fluid Anion Specialty Chemicals

TrunnionMill Bearing Fluid Improve High-Temperature Trunnion and Mill Bearing Overloading. We solve trunnion and mill bearing lube problems for people in the chemical, waste, processing, lime, cement and stone industries. We provide expert consulting and field troubleshooting support to help our customers find the best lubricating products.

Ball Mill Trunnion Hollow Shaft For Ball Mill Customization

AGICO CEMENT ensures that the heat treatment is evenly heated Advanced technology As a high-quality ball mill trunnion casting enterprise, AGICO CEMENT has a series of quality inspection technologies for steel castings to ensure the quality of steel castings. Strong production capacity

Analysis of the criticality of flaws found in trunnion of grinding

201631Oil lubrication failure on grinding mill trunnion bearings causes thermal stresses in surfaces and cracks at low stress region. • A contact temperature of 150 °C may causes a stress over the yield strength of the trunnion nodular cast iron.. The use of standard BS 7910 on fatigue crack propagation in the trunnion proved to be more