مسكن

>

roughing mill roughing mill

مسكن

>

roughing mill roughing mill

منتج

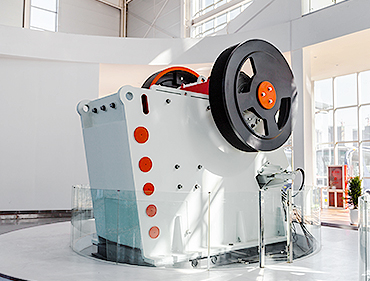

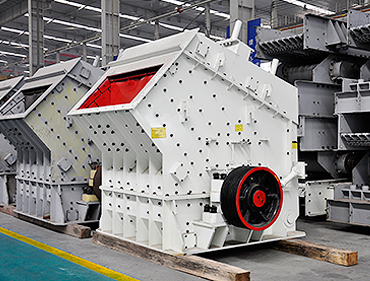

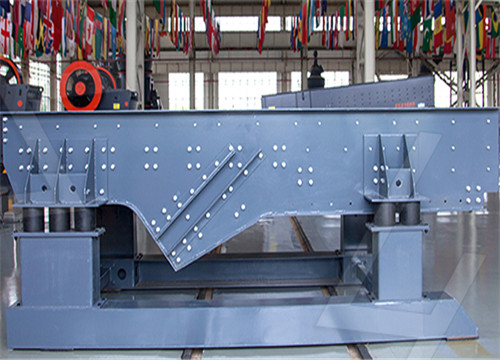

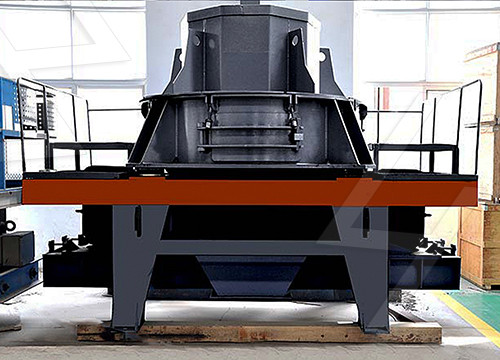

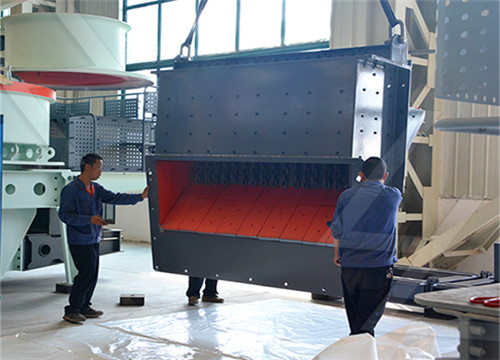

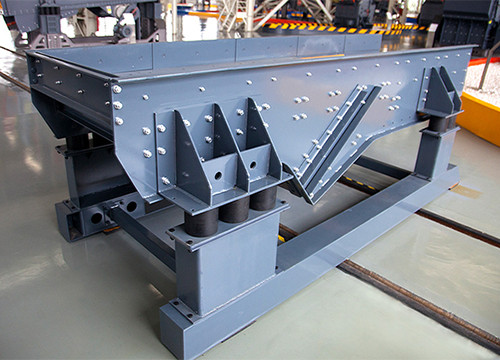

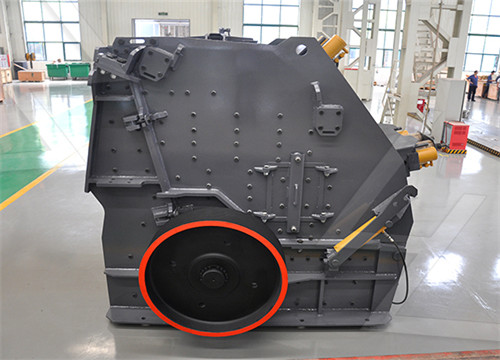

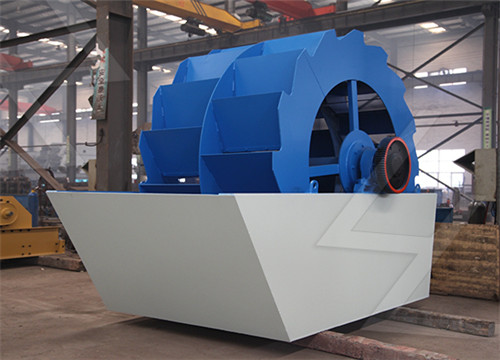

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

roughing mill roughing mill

Roughing Mill an overview ScienceDirect Topics

Consider the hot rolling of a low-carbon steel strip in a single stand roughing mill. Let the entry thickness of the slab be 20 mm and its width to be 2000 mm. Its resistance to

OSG Taps End Mills Drills Indexable Composite Tooling

Roughing Roughing End Mills Roughing end mills feature nicks or serrations along the cutting edge which act as mechanical chip breakers to produce shorter, more

Roughing End Mills McMaster-Carr

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material.

Profile milling Coromant

Profile Milling ProcessChoice of ToolsApplication Checklist For Profile MillingHow to Reduce Vibrations

Profile milling covers the multi-axis milling of convex and concave shapes in two and three dimensions. The larger the component and the more complicated the configuration of the machine, the more important the planning of the profile milling process becomes. The machining process should be divided into at least three operation types: 1. Roughing/s...

Roughing End Mills Travers Tool

Roughing End Mills, also known as ripping cutters or hoggers, are designed to remove large amounts of metal quickly and more efficiently than standard end mills. Coarse

Solid Carbide End Milling MaxiMet™ Solid Carbide End Mill for

MaxiMet™ Solid Carbide End Mill for Roughing and Finishing of Aluminum. Metric. Inch. SAP Material Number: : ISO Catalog Number: ABDF0625J2BQ: ANSI Catalog

Roughing vs. Finishing End Mill: How Do They Differ?

2022821Roughing is primarily used to remove excess material from a piece. In addition, roughing is conducted at a higher feed rate and a deeper cut depth. A

Analysis of Spalling in Roughing Mill Backup Rolls of Wide and

The roughing mill withstood extreme service conditions with long service cycles for backup and work rolls, a large variety of the same width rolling campaigns, severe and non

ROSWELL MILLS A Southern TrilogyTHE CIVIL WAR

Mill can be found. The mills were burned by Union forces with the help of some of the Roswell Mill employees. Only the 1853 mill was rebuilt after the war and used until

OSG Taps End Mills Drills Indexable Composite Tooling

Roughing. Roughing End Mills Roughing end mills feature nicks or serrations along the cutting edge which act as mechanical chip breakers to produce shorter, more manageable chips. Typically used in “roughing” applications where deep depths of cut and low horsepower machine capability are present. View Roughing End Mill Offering

High-Performance Solid Carbide • Roughing End Mills Kennametal

KenCut™ RR Solid Carbide End Mill for Roughing of Steels, Stainless Steel, Cast Iron, High Temperature Alloys (11 Products) Slotting: Square End Ramping: Blank Side

Roughing End Mills McMaster-Carr

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

Roughing Carbide End Mills Regal Cutting Tools

Select Regal roughing end mills for difficult roughing of hardened steels or high velocity milling of aluminum and other non-ferrous materials. These 20 degree helix tools in both coarse and fine pitch tools are made from sub micro-grain carbide and designed for either wet or dry high speed milling applications in either tool or hardened steel.

Roughing End Mills MSC Industrial Supply

Roughing end mills, also known as hog mills, are used to quickly remove large amounts of material during heavier operations. The tooth design allows for little to no vibration, but leaves a rougher finish. About MSC Events Press Releases Investor Relations Community Relations Career Opportunities.

Roughing GWS Tool Group

Roughing GWS Tool Group Milling Roughing Alumigator™ Series 1010 ART 3 Flute Chip Breaker End Mill Carbide, Chip Breaker, 37° Helix, 3FL, Corner Radius, h6, Non-Center Cutting, Bright N1 N2 Alumigator™ Series 1015 AST 3 Flute Chip Breaker End Mill Carbide, Chip Breaker, 37° Helix, 3FL, Corner Radius, Square, h6, Bright N1 N2

High-Performance Roughing Carbide Corner

Corner-Chamfer End Mills High-Performance Roughing Carbide Corner-Chamfer End Mills Search Feedback Filters Previously Purchased Sign in to view purchased products In Stock at Branch Select a Pickup Branch

Roughing End Mills Travers Tool

Roughing End Mills, also known as ripping cutters or hoggers, are designed to remove large amounts of metal quickly and more efficiently than standard end mills. Coarse tooth roughing end mills remove large chips for heavy cuts, deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing application.

Solid Carbide End Milling MaxiMet™ Solid Carbide End Mill for

MaxiMet™ Solid Carbide End Mill for Roughing and Finishing of Aluminum. Metric. Inch. SAP Material Number: : ISO Catalog Number: ABDF0625J2BQ: ANSI Catalog Number: ABDF0625J2BQ: Grade: K600: Adapter Style Machine Side: Straight-Cylindrical [D3] Neck Diameter : 14.9000 mm [D3] Neck Diameter .5866 in

Around Roughing End Mill: A Complete Guide Huana Tools

202265Roughing end mills are a solution that can save money while maintaining the original operating capability for individuals who are willing to consider other options. The roughing end mill may save you anywhere from fifty to ninety percent of the price of a brand new tool, making it one of the most cost-effective ways to reduce your expenses.

Roughing/Finishing End Mills Travers Tool

Roughing/Finishing End Mills are used for removing large amounts of material quickly but leaving behind a finish that's almost as smooth as a traditional end mill. Saves time over a traditional two-step hoggingfinishing process. Easily resharpened without altering form for extended tool life. A wide range of coatings, tool material and number of flutes are

Analysis of Spalling in Roughing Mill Backup Rolls of Wide and

The roughing mill withstood extreme service conditions with long service cycles for backup and work rolls, a large variety of the same width rolling campaigns, severe and non-uniform wear contours of backup and work rolls. Analysis of cyclic stress applied on backup rolls indicated that contact stress played a dominant role in rolling contact

Roughing End Mills (Carbide) Carbide Square End Mills MISUMI

Roughing End Mill Regular 3-Flute 3127 GUHRING Roughing endmill dedicated for aluminum. Configure Now Ships as soon as 5 Days CoroMill Plura, Carbide Solid End Mill Roughing SANDVIK Unique shape exhibits high performance Configure Now Ships as soon as 4 Days Carbide 4-Flute Variable Split Variable Lead Medium Roughing End Mill

Finishing Mill an overview ScienceDirect Topics

Roughing mill rolling of reheated slab: The roughing mill usually consists of one or two roughing stands in which the slab is hot rolled back and forth 5 or 7 times repeatedly to reach the minimum thickness requirement. The roughing mill also contains edger rolls that are used to roll the edge of slab and center it.

OSG Taps End Mills Drills Indexable Composite Tooling

Roughing Roughing End Mills Roughing end mills feature nicks or serrations along the cutting edge which act as mechanical chip breakers to produce shorter, more manageable chips. Typically used in “roughing” applications where deep depths of cut and low horsepower machine capability are present. View Roughing End Mill Offering

High-Performance Solid Carbide • Roughing End Mills Kennametal

KenCut™ RR Solid Carbide End Mill for Roughing of Steels, Stainless Steel, Cast Iron, High Temperature Alloys (11 Products) Slotting: Square End Ramping: Blank Side

High-Performance Roughing Carbide Corner

Corner-Chamfer End Mills High-Performance Roughing Carbide Corner-Chamfer End Mills Search Feedback Filters Previously Purchased Sign in to view purchased products In Stock at Branch Select a Pickup Branch

Solid Carbide End Milling MaxiMet™ Solid Carbide End Mill for

MaxiMet™ Solid Carbide End Mill for Roughing and Finishing of Aluminum. Metric. Inch. SAP Material Number: : ISO Catalog Number: ABDF0625J2BQ: ANSI Catalog Number: ABDF0625J2BQ: Grade: K600: Adapter Style Machine Side: Straight-Cylindrical [D3] Neck Diameter : 14.9000 mm [D3] Neck Diameter .5866 in

Roughing End Mills Travers Tool

Roughing End Mills, also known as ripping cutters or hoggers, are designed to remove large amounts of metal quickly and more efficiently than standard end mills. Coarse tooth roughing end mills remove large chips for heavy cuts, deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing application.

WIDIA™ VSM11 Series 0°/90° Shoulder MillsMetalworking

2-Edged, 90 Degree Shoulder Mill. VSM11 is a 2-Edged, 90° Victory™ Shoulder Mill (VSM) delivering low horsepower consumption, versatility and soft cutting action in light, precise machining to medium roughing. Use this shoulder mill in profiling, slotting, ramping, helical and circular interpolation, and other milling applications.

Roughing/Finishing End Mills Travers Tool

Roughing/Finishing End Mills are used for removing large amounts of material quickly but leaving behind a finish that's almost as smooth as a traditional end mill. Saves time over a traditional two-step hoggingfinishing process. Easily resharpened without altering form for extended tool life. A wide range of coatings, tool material and number of flutes are

Roughing End Mills For Aluminum The Carbide End Mill Store

Roughing End Mills For Aluminum CNC rough milling of aluminum can be difficult, because the material can stick to the flutes and the chips can pack. Today's high performance carbide cutting tools for aluminum have large flutes to yield the maximum metal removal rates possible.

Around Roughing End Mill: A Complete Guide Huana Tools

202265Roughing end mills are a solution that can save money while maintaining the original operating capability for individuals who are willing to consider other options. The roughing end mill may save you anywhere from fifty to ninety percent of the price of a brand new tool, making it one of the most cost-effective ways to reduce your expenses.

Analysis of Spalling in Roughing Mill Backup Rolls of Wide and

The roughing mill withstood extreme service conditions with long service cycles for backup and work rolls, a large variety of the same width rolling campaigns, severe and non-uniform wear contours of backup and work rolls. Analysis of cyclic stress applied on backup rolls indicated that contact stress played a dominant role in rolling contact

Roughing Cobalt Ball End Mills Grainger Industrial Supply

52 products. Roughing ball end mills remove large amounts of material from a workpiece more quickly than finishing ball end mills. Sometimes called corn cobs and hog mills, roughing end mills have a tooth design that minimizes vibration during milling tasks but leaves a rough finish on the workpiece. Cobalt end mills can be used at higher

Material Removal Rate [Optimizing MRR for Bigger Profits]

Some tools are purpose made for roughing and can’t be used for finished. The serrated or “corn cob” rougher is a great example: Those serrations break up the chips so they’re easier to evacuate. This type of cutter will buzz through roughing cuts faster than regular solid end mills, and therefore they have higher metal removal rates.

Roughing Mill Hot Rolling Steel AMETEK Land

Roughing Mill Hot Rolling Steel AMETEK Land English Login INDUSTRIES + Steel + Iron to Steel Hot Rolling Mill Cold Rolling CAL Continuous Annealing Line CGL Continuous Galvanizing Line Rod Mill Aluminium + Aluminium Strip Mill Aluminium Extrusion Plant Aluminium Forging Aluminium Other Applications Speciality Metals +

Roughing End Mills (HSS) Square HSS End Mills MISUMI

The roughing and finishing end mill features a unique trapezoid blade shape derived from consideration for finishing cutting as well as heavy cutting. Nick perpendicular to shaft which withstands heavy cutting and boasts great blade tip