مسكن

>

high efficiency durable sand crushing plate from suriname

مسكن

>

high efficiency durable sand crushing plate from suriname

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

high efficiency durable sand crushing plate from suriname

Sustainable production of crushed sands using crushing

Impact crushing technology for producing crushed sands. Our rotor impact mill (type RPM) and rotor centrifugal crusher (type RSMX) crushing systems ensure best results in the production of crushed sand. Both

7 Types of Stone Crusher and How to Choose the Best?

2021923Advantages: large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable operation, low failure rate, and not

4 Types of Stone Crushers' Maintenance and Efficient Impr5 Types Of Stone Crushers Application and Maintenance•

Sand production crusher, Sand production crushing plant

VSI crusher RSMX series. stationary sand production. Capacity: 30 t/h 500 t/h. Motor power: 160 kW 400 kW. Weight: 7,500 kg 20,200 kg. The rotor centrifugal crusher

Heavy Industries In Suriname Crusher Mills

Heavy Industries In Suriname CKC Machinehandel Surmac N.V. (Surmac) Kersten CKC Machinehandel Surmac N.V. (Surmac) was established in 1957, mainly to provide the

Joyal-PCL Sand Making Machine,PCL Vertical Shaft Impact

VSI Sand Making Machine. HPC Cone Crusher. Solutions. River Stone Crushing Plant. Feldspar Stone Crushing Plant. Basalt Stone Crushing Plant. Granite Stone Crushing

Sand Making Plant for Sale Eastman Rock Crusher

Capacity: 120-640t/h. Input size: 30-50mm. Wheel Type Sand Washer. Capacity: 15-200TPH. Feeding size: ≤10. Spiral Type Sand Washer. Capacity: 30-200TPH. Motor: 7.5

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of

4 Types of Stone Crushers' Maintenance and Efficient

20232154 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and

6 Types of Sand Making Machine and How to Choose the

2023215It has strong processing capacity, strong material adjustability and high sand making efficiency. Applicable materials: Same as HVI sand making machine, it is

Impact Crusher Machines Williams Patent Crusher

For help deciding which impact crusher is right for your industrial application, contact our engineers at (314) 433-5464, email us at info@williamscrusher, or locate an agent

Evaluation of Influence of Crushing Plates Shape on SpringerLink

201796This stone is a continuation of work performed at the Institute of Construction Machinery Engineering in area of shape optimization of the crushing plates (Ciężkowski 2012a, b; Ciężkowski et al 2013).Studies of this type are essential for increasing the performance of the crushing process, reducing energy consumption and achieve

High pressure grinding rolls (HPGR) Metso Outotec

Robust HRC™ high pressure grinding rolls (HPGR) High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed

Aggregate Crushing Plant-High Safety High Efficiency Stable

All kinds of crushing plants have a variety of configurations, users can also choose their own configuration according to their own needs.The device can be formed according to different crushing process requirements to form “first broken and then broken” process, crushing and screening can also be used separately.

Sand Making Plant for Sale Eastman Rock Crusher

Sand Making Plant for Sale Eastman Rock Crusher sand making Plant VSI Sand Making Machine Capacity: 120-640t/h Input size: 30-50mm Wheel Type Sand Washer Capacity: 15-200TPH Feeding size: ≤10 Spiral Type Sand Washer Capacity: 30-200TPH Motor: 7.5-22Kw

(PDF) Application of The New Shape Crushing Plate in Machine Crushing

20191029PDF The results of studies of the crushing process in a double toggle jaw crusher are presented. This process was carried out on six sets of crushing Find, read and cite all the research

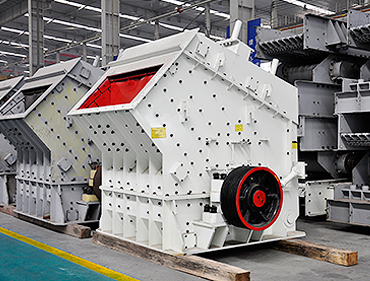

The stone crusher is the key crushing equipment in sand

20191210Generally, impact crusher is a new type and high efficiency stone crusher. It has the characteristics of small size, simple structure, large crushing rate, low energy consumption and high

Perforated Plate The Western Group TWG

Perforated plates are often used in scalping operations to improve overall system efficiency. Appropriate media selection can reduce fines before they reach crushing, which will dramatically improve capacity. In addition, choosing the right screen media for your application can increase wear life and reduce maintenance downtime. PLATE

HPT Hydraulic Cone Crusher,high efficiency Hydraulic Cone Cru

HPT series high efficiency Hydraulic Cone Crusher is a world-level cone crusher developed from the up-to-minute technology of Germany. Unique interparticle crushing action, Advanced hydraulic system, Integration of the hydraulic station and lubrication system,Advanced liner retention technology,Much more reliable.The cone crusher ’s

Crushing Efficiency Factors Mineral ProcessingMetallurgy

2016712Single layer particle crushing was taken to be 100% efficient, and measurements were made of the relative efficiencies, i.e., the ratio of the amounts of energy required to achieve the same degree of plate separation in crushing the multi-layer particles to reduction ratios of 1.16, 1.28, and 1.40 (the reduction ratio is defined as the

Machine Design 1 L65 Crushing of Rivets or Plates and Crushing Efficiency

2020416Machine Design 1 L65 Crushing of Rivets or Plates and Crushing Efficiency YouTube Sign in to confirm your age 0:00 / 19:10 BATHINDA Machine Design 1 L65 Crushing of Rivets or

: Dr Balraj Singh Brar

Artificial Sand What Is It and How to Make It Fote Machinery

2023215Artificial sand, also called crushed sand or mechanical sand (m sand), refers to rocks, mine tailings or industrial waste granules with a particle size of less than 4.75 mm. It is processed by mechanical crushing and sieving. In China, the artificial sand was mainly used in the construction of hydropower systems.

Ambica Crushtech-Crushing and Screening Solutions Provider

Titan Crushing introduces 50-100-150 TPH plants to produce sand with very low operating cost Titan Crushing, which manufactures crushing and screening solutions under the brand name Diamond Crushers, has expanded its range from toggle crushers to grizzly, jaw cones, and vertical shaft impactors for stationary crushing.

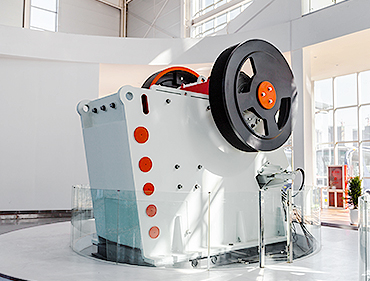

Crushing Equipment ZENITH Crusher

Crushing Equipment. ZENITH's stone crusher is designed to achieve larger productivity and higher crushing ratio. From large primary crushers jaw crushers and impact crushers to cone crushers and VSI sand makers as secondary or tertiary stone crushers, ZENITH can supply the right crushers as well as complete crushing lines to meet your requirements.

Sand production crusher, Sand production crushing plant All

VSI crusher RSMX series. stationary sand production. Capacity: 30 t/h 500 t/h. Motor power: 160 kW 400 kW. Weight: 7,500 kg 20,200 kg. The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materials.

Sustainable production of crushed sands using

Impact crushing technology for producing crushed sands. Our rotor impact mill (type RPM) and rotor centrifugal crusher (type RSMX) crushing systems ensure best results in the production of crushed sand. Both

Aggregate Crushing Plant-High Safety High

All kinds of crushing plants have a variety of configurations, users can also choose their own configuration according to their own needs.The device can be formed according to different crushing process requirements to form

High pressure grinding rolls (HPGR) Metso Outotec

Robust HRC™ high pressure grinding rolls (HPGR) High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed

(PDF) Application of The New Shape Crushing Plate in

20191029PDF The results of studies of the crushing process in a double toggle jaw crusher are presented. This process was carried out on six sets of crushing Find, read and cite all the research

Sand Making Plant for Sale Eastman Rock Crusher

Sand Making Plant for Sale Eastman Rock Crusher sand making Plant VSI Sand Making Machine Capacity: 120-640t/h Input size: 30-50mm Wheel Type Sand Washer Capacity: 15-200TPH Feeding size: ≤10 Spiral Type

Evaluation of Influence of Crushing Plates Shape on SpringerLink

201796This stone is a continuation of work performed at the Institute of Construction Machinery Engineering in area of shape optimization of the crushing plates (Ciężkowski 2012a, b; Ciężkowski et al 2013).Studies of this type are essential for increasing the performance of the crushing process, reducing energy consumption and achieve

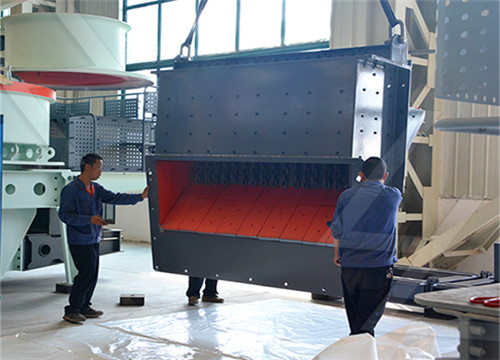

Hammer Crusher Machine Big Crushing Ratio And High Efficiency

Our hammer crusher machine can save the energy more than 50% than the same type of products. This can reduce your running cost. The use of wear-resistant material can reduce the wear of the lining plate and increase the service time. The body of hammer for crusheradopts sealing structure, which well solves the problem of dust pollution and dust

Crushing Efficiency Factors Mineral Processing

2016712Single layer particle crushing was taken to be 100% efficient, and measurements were made of the relative efficiencies, i.e., the ratio of the amounts of energy required to achieve the same degree of

HPT Hydraulic Cone Crusher,high efficiency Hydraulic

HPT series high efficiency Hydraulic Cone Crusher is a world-level cone crusher developed from the up-to-minute technology of Germany. The cone crusher not only improves the production capacity and crushing

Machine Design 1 L65 Crushing of Rivets or Plates and Crushing Efficiency

2020416Machine Design 1 L65 Crushing of Rivets or Plates and Crushing Efficiency YouTube Sign in to confirm your age 0:00 / 19:10 BATHINDA Machine Design 1 L65 Crushing of Rivets or

: Dr Balraj Singh Brar

The stone crusher is the key crushing equipment in sand

20191210Generally, impact crusher is a new type and high efficiency stone crusher. It has the characteristics of small size, simple structure, large crushing rate, low energy consumption and high

Crushing Equipment ZENITH Crusher

Crushing Equipment. ZENITH's stone crusher is designed to achieve larger productivity and higher crushing ratio. From large primary crushers jaw crushers and impact crushers to cone crushers and VSI sand makers as secondary or tertiary stone crushers, ZENITH can supply the right crushers as well as complete crushing lines to meet your requirements.

Artificial Sand What Is It and How to Make It Fote Machinery

2023215Artificial sand, also called crushed sand or mechanical sand (m sand), refers to rocks, mine tailings or industrial waste granules with a particle size of less than 4.75 mm. It is processed by mechanical crushing and sieving. In China, the artificial sand was mainly used in the construction of hydropower systems.

Sand production crusher, Sand production crushing plant All

VSI crusher RSMX series. stationary sand production. Capacity: 30 t/h 500 t/h. Motor power: 160 kW 400 kW. Weight: 7,500 kg 20,200 kg. The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materials.

Sand production crusher, Sand production crushing plant

VSI crusher RSMX series. stationary sand production. Capacity: 30 t/h 500 t/h. Motor power: 160 kW 400 kW. Weight: 7,500 kg 20,200 kg. The rotor centrifugal crusher

Heavy Industries In Suriname Crusher Mills

Heavy Industries In Suriname CKC Machinehandel Surmac N.V. (Surmac) Kersten CKC Machinehandel Surmac N.V. (Surmac) was established in 1957, mainly to provide the

Joyal-PCL Sand Making Machine,PCL Vertical Shaft Impact

VSI Sand Making Machine. HPC Cone Crusher. Solutions. River Stone Crushing Plant. Feldspar Stone Crushing Plant. Basalt Stone Crushing Plant. Granite Stone Crushing

Sand Making Plant for Sale Eastman Rock Crusher

Capacity: 120-640t/h. Input size: 30-50mm. Wheel Type Sand Washer. Capacity: 15-200TPH. Feeding size: ≤10. Spiral Type Sand Washer. Capacity: 30-200TPH. Motor: 7.5

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of

4 Types of Stone Crushers' Maintenance and Efficient

20232154 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and

6 Types of Sand Making Machine and How to Choose the

2023215It has strong processing capacity, strong material adjustability and high sand making efficiency. Applicable materials: Same as HVI sand making machine, it is

Impact Crusher Machines Williams Patent Crusher

For help deciding which impact crusher is right for your industrial application, contact our engineers at (314) 433-5464, email us at info@williamscrusher, or locate an agent

Evaluation of Influence of Crushing Plates Shape on SpringerLink

201796This stone is a continuation of work performed at the Institute of Construction Machinery Engineering in area of shape optimization of the crushing plates (Ciężkowski 2012a, b; Ciężkowski et al 2013).Studies of this type are essential for increasing the performance of the crushing process, reducing energy consumption and achieve

High pressure grinding rolls (HPGR) Metso Outotec

Robust HRC™ high pressure grinding rolls (HPGR) High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed

Aggregate Crushing Plant-High Safety High Efficiency Stable

All kinds of crushing plants have a variety of configurations, users can also choose their own configuration according to their own needs.The device can be formed according to different crushing process requirements to form “first broken and then broken” process, crushing and screening can also be used separately.

Sand Making Plant for Sale Eastman Rock Crusher

Sand Making Plant for Sale Eastman Rock Crusher sand making Plant VSI Sand Making Machine Capacity: 120-640t/h Input size: 30-50mm Wheel Type Sand Washer Capacity: 15-200TPH Feeding size: ≤10 Spiral Type Sand Washer Capacity: 30-200TPH Motor: 7.5-22Kw

(PDF) Application of The New Shape Crushing Plate in Machine Crushing

20191029PDF The results of studies of the crushing process in a double toggle jaw crusher are presented. This process was carried out on six sets of crushing Find, read and cite all the research

The stone crusher is the key crushing equipment in sand

20191210Generally, impact crusher is a new type and high efficiency stone crusher. It has the characteristics of small size, simple structure, large crushing rate, low energy consumption and high

Perforated Plate The Western Group TWG

Perforated plates are often used in scalping operations to improve overall system efficiency. Appropriate media selection can reduce fines before they reach crushing, which will dramatically improve capacity. In addition, choosing the right screen media for your application can increase wear life and reduce maintenance downtime. PLATE

HPT Hydraulic Cone Crusher,high efficiency Hydraulic Cone Cru

HPT series high efficiency Hydraulic Cone Crusher is a world-level cone crusher developed from the up-to-minute technology of Germany. Unique interparticle crushing action, Advanced hydraulic system, Integration of the hydraulic station and lubrication system,Advanced liner retention technology,Much more reliable.The cone crusher ’s

Crushing Efficiency Factors Mineral ProcessingMetallurgy

2016712Single layer particle crushing was taken to be 100% efficient, and measurements were made of the relative efficiencies, i.e., the ratio of the amounts of energy required to achieve the same degree of plate separation in crushing the multi-layer particles to reduction ratios of 1.16, 1.28, and 1.40 (the reduction ratio is defined as the

Machine Design 1 L65 Crushing of Rivets or Plates and Crushing Efficiency

2020416Machine Design 1 L65 Crushing of Rivets or Plates and Crushing Efficiency YouTube Sign in to confirm your age 0:00 / 19:10 BATHINDA Machine Design 1 L65 Crushing of Rivets or

Artificial Sand What Is It and How to Make It Fote Machinery

2023215Artificial sand, also called crushed sand or mechanical sand (m sand), refers to rocks, mine tailings or industrial waste granules with a particle size of less than 4.75 mm. It is processed by mechanical crushing and sieving. In China, the artificial sand was mainly used in the construction of hydropower systems.

Ambica Crushtech-Crushing and Screening Solutions Provider

Titan Crushing introduces 50-100-150 TPH plants to produce sand with very low operating cost Titan Crushing, which manufactures crushing and screening solutions under the brand name Diamond Crushers, has expanded its range from toggle crushers to grizzly, jaw cones, and vertical shaft impactors for stationary crushing.

Crushing Equipment ZENITH Crusher

Crushing Equipment. ZENITH's stone crusher is designed to achieve larger productivity and higher crushing ratio. From large primary crushers jaw crushers and impact crushers to cone crushers and VSI sand makers as secondary or tertiary stone crushers, ZENITH can supply the right crushers as well as complete crushing lines to meet your requirements.

Sand production crusher, Sand production crushing plant All

VSI crusher RSMX series. stationary sand production. Capacity: 30 t/h 500 t/h. Motor power: 160 kW 400 kW. Weight: 7,500 kg 20,200 kg. The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materials.

Sustainable production of crushed sands using

Impact crushing technology for producing crushed sands. Our rotor impact mill (type RPM) and rotor centrifugal crusher (type RSMX) crushing systems ensure best results in the production of crushed sand. Both

Aggregate Crushing Plant-High Safety High

All kinds of crushing plants have a variety of configurations, users can also choose their own configuration according to their own needs.The device can be formed according to different crushing process requirements to form

High pressure grinding rolls (HPGR) Metso Outotec

Robust HRC™ high pressure grinding rolls (HPGR) High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed

(PDF) Application of The New Shape Crushing Plate in

20191029PDF The results of studies of the crushing process in a double toggle jaw crusher are presented. This process was carried out on six sets of crushing Find, read and cite all the research

Sand Making Plant for Sale Eastman Rock Crusher

Sand Making Plant for Sale Eastman Rock Crusher sand making Plant VSI Sand Making Machine Capacity: 120-640t/h Input size: 30-50mm Wheel Type Sand Washer Capacity: 15-200TPH Feeding size: ≤10 Spiral Type

Evaluation of Influence of Crushing Plates Shape on SpringerLink

201796This stone is a continuation of work performed at the Institute of Construction Machinery Engineering in area of shape optimization of the crushing plates (Ciężkowski 2012a, b; Ciężkowski et al 2013).Studies of this type are essential for increasing the performance of the crushing process, reducing energy consumption and achieve

Hammer Crusher Machine Big Crushing Ratio And High Efficiency

Our hammer crusher machine can save the energy more than 50% than the same type of products. This can reduce your running cost. The use of wear-resistant material can reduce the wear of the lining plate and increase the service time. The body of hammer for crusheradopts sealing structure, which well solves the problem of dust pollution and dust

Crushing Efficiency Factors Mineral Processing

2016712Single layer particle crushing was taken to be 100% efficient, and measurements were made of the relative efficiencies, i.e., the ratio of the amounts of energy required to achieve the same degree of

HPT Hydraulic Cone Crusher,high efficiency Hydraulic

HPT series high efficiency Hydraulic Cone Crusher is a world-level cone crusher developed from the up-to-minute technology of Germany. The cone crusher not only improves the production capacity and crushing

Machine Design 1 L65 Crushing of Rivets or Plates and Crushing Efficiency

2020416Machine Design 1 L65 Crushing of Rivets or Plates and Crushing Efficiency YouTube Sign in to confirm your age 0:00 / 19:10 BATHINDA Machine Design 1 L65 Crushing of Rivets or

The stone crusher is the key crushing equipment in sand

20191210Generally, impact crusher is a new type and high efficiency stone crusher. It has the characteristics of small size, simple structure, large crushing rate, low energy consumption and high

Crushing Equipment ZENITH Crusher

Crushing Equipment. ZENITH's stone crusher is designed to achieve larger productivity and higher crushing ratio. From large primary crushers jaw crushers and impact crushers to cone crushers and VSI sand makers as secondary or tertiary stone crushers, ZENITH can supply the right crushers as well as complete crushing lines to meet your requirements.

Artificial Sand What Is It and How to Make It Fote Machinery

2023215Artificial sand, also called crushed sand or mechanical sand (m sand), refers to rocks, mine tailings or industrial waste granules with a particle size of less than 4.75 mm. It is processed by mechanical crushing and sieving. In China, the artificial sand was mainly used in the construction of hydropower systems.

Sand production crusher, Sand production crushing plant All

VSI crusher RSMX series. stationary sand production. Capacity: 30 t/h 500 t/h. Motor power: 160 kW 400 kW. Weight: 7,500 kg 20,200 kg. The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materials.