مسكن

>

how to make a flail flotation cell machine mill

مسكن

>

how to make a flail flotation cell machine mill

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

how to make a flail flotation cell machine mill

(PDF) Flash Milling Inside a Flotation Cell researchgate.net

202116Flash Milling Inside a Flotation Cell Authors: Johnny T. Kalala DRA Global, South Africa Abstract Description of the novel technology ( Kalala Mill) being implemented at one platinum...

Flash Milling inside a flotation cell Dr Johnny T. Kalala

The challenges to operate a mill inside a flotation cell are related to the: i) safety, ii) confined space, iii) lower percentage solids inside a flotation cell, iv) disturbing the

Flotation Machine an overview ScienceDirect Topics

The flotation machine must perform a series of complicated functions. Some of the more obvious are: 1. Good mixing of pulp. To be effective, a flotation machine should

Types of Flotation Machines JXSC Machine7 Factors Affecting Froth Flotation Process JXSC Machine•

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

Mechanical flotation cells can be broken down into two broad categories based on how air is introduced to the cell. In a self aspirated flotation cell air is introduced to the slurry,

: 266KB

Flash Flotation with Closed Circuit Grinding

20164144 Options for Flash Flotation in a Closed Circuit Grinding Plant A greater amount of granular higher grade concentrates can be

:13

Flash Flotation Cell Mineral ProcessingMetallurgy

201661This phenomenal recovery is made by a Unit Flotation Cell installed between the ball mill and classifier, and a coarse high grade rougher concentrate averaging 65% to 70% lead is obtained without

Flotation Test Machine

Essa® FTM101 Flotation Test Machine. The best features of FTM101 are the interchangeable parts that make it suitable for a range of metallurgical test work. Impellers, shafts and diffusers are available in various sizes

4 Common Problems and Solutions Met in the Flotation

20191129There are many types of flotation cells. But the flotation cell that most widely used in the flotation plant is the mechanical agitation flotation cell. It has complex structure, which often has the effect on the

Flotation machine, Flotation cell YouTube

2017726flotation machine works, slurry is inhaled from the bottom of the cell to the space between impellers. Meanwhile, the low-pressure air send by fan is sent to...

: jackwen520

Flotation ANDRITZ

Inspection and maintenance-friendly construction. SelectaFlot flotation combines both primary and secondary flotation in one compact unit, resulting in advantages for inspection and maintenance. In order to save

Flash Milling inside a flotation cell Dr Johnny T. Kalala

The challenges to operate a mill inside a flotation cell are related to the: i) safety, ii) confined space, iii) lower percentage solids inside a flotation cell, iv) disturbing the zones and flow

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

Mechanical flotation cells can be broken down into two broad categories based on how air is introduced to the cell. In a self aspirated flotation cell air is introduced to the slurry,the vacuum created by the rotorusing . In a forced air flotation cell air is generated external to the cell by a low pressure blower,,and pumped down the

(PDF) Flash Milling Inside a Flotation Cell

202116The challenge s to operate a mill insid e a flotatio n cell are relate d to the: i) safet y, ii) confin ed space, iii) lower percen tage solids insi de a flotat ion cell, iv) di sturbin g the

Flash Flotation with Closed Circuit Grinding

20164144 Options for Flash Flotation in a Closed Circuit Grinding Plant A greater amount of granular higher grade concentrates can be produced and, in general, overall plant recovery is improved by

1 Froth Flotation Fundamental Principles

no flotation can occur. Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5. Figure 5: Simplified schematic of a conventional flotation cell. The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator.

Flotation Flowsheets 911metallurgist

20151214This flowsheet shows the use of a “Sub-A” Flotation Machines for selective flotation producing high grade lead and zinc products. The Unit Flotation Cell and Mineral Jig recover 73.2 percent

Continuous Flotation Cell GTEK

Working Principle. FX Flotation Machine is a kind of impeller mechanical flotation machine which mainly consist of cells, the impeller system, mainshaft system and scarping divce.. 1. To adjust the level of slurry in

Flotation Column: A Process Unit for Cleaning Up Paper

Flotation deinking is a key unit operation in most stone recycling plants for the removal of hydrophobic contaminants from pulp [12]. There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectors.

4 Common Problems and Solutions Met in the

20191129Gate structure is simple and located in the tail of flotation machine. Its main function is to adjust the level of the cell.In the process of installation and debugging, the gate is often used, so the hand wheel is

Forced-air flotation cell

Increased fine particle recovery Specifically designed to maximise fine particle recovery, the Dorr-Oliver flotation cell is the most energy efficient, technically advanced, forced-air flotation machine on the market. Its air dispersion capabilities exceed all competitive forced air designs an important consideration for fine particle recovery.

Laboratory Flotation Cell (with replaceable tanks) GTEK

D12 Lab Flotation Machine is mainly consist of the following parts: lifting mechanism, machine body, stator and impeller part, inverter and control system. All the parts are connected to the vertical column. The main

Flotation Cells Prominer (Shanghai) Mining Technology Co.,Ltd.

Based on the function of chemical reagent, it can be classified as collectors, frothers and modifiers. Technical Specifications of SF Flotation Cells: Technical specifications of XCF/KYF Series Flotation Cells Submit your requirement below for mineral processing proposal! Please contact whatsapp number via +86 for detailed information!

Flotation Test Machine

Essa® FTM101 Flotation Test Machine. The best features of FTM101 are the interchangeable parts that make it suitable for a range of metallurgical test work. Impellers, shafts and diffusers are available in various sizes and capacities to suit your needs. The flotation cells also come in four different capacities from 0.5 up to five litres.

RCS™ flotation machines Metso Outotec

Enhanced performance. Metso Outotec RCS™ flotation machines have made several advances in flotation design and technology. Maximize bubble-particle contact within the mechanism and the flotation tank leads to enhanced performance. Effective air dispersion and distribution throughout the cell volume helps in smooth froth surface and removal.

(PDF) Flash Milling Inside a Flotation Cell

202116The challenge s to operate a mill insid e a flotatio n cell are relate d to the: i) safet y, ii) confin ed space, iii) lower percen tage solids insi de a flotat ion cell, iv) di sturbin g the

Flash Milling inside a flotation cell Dr Johnny T. Kalala

The challenges to operate a mill inside a flotation cell are related to the: i) safety, ii) confined space, iii) lower percentage solids inside a flotation cell, iv) disturbing the zones and flow

1 Froth Flotation Fundamental Principles

no flotation can occur. Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5. Figure 5: Simplified schematic of a conventional flotation cell. The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator.

Flotation Test Machine

Essa® FTM101 Flotation Test Machine. The best features of FTM101 are the interchangeable parts that make it suitable for a range of metallurgical test work. Impellers, shafts and diffusers are available in various sizes

Flotation CellsMachines JXSC Machine

When the JJF mechanical agitation flotation machine is working, the rotor creates a fluid vortex inside the standpipe and the draft tube, and causes a sufficient vacuum area to induce air into the standpipe through the air inlet duct. The induced air is mixed with pulp between the impeller and stator.

Laboratory Flotation Cell (with replaceable tanks) GTEK

D12 Lab Flotation Machine is mainly consist of the following parts: lifting mechanism, machine body, stator and impeller part, inverter and control system. All the parts are connected to the vertical column. The main

Continuous Flotation Cell GTEK

FX mechanical agitated Continuous Flotation Machine is suitable for continuous flotation test or semi-industrial production test of a small amount of minerals in the laboratory by flotation method. It is made up of

Flotation Column: A Process Unit for Cleaning Up Paper

Flotation deinking is a key unit operation in most stone recycling plants for the removal of hydrophobic contaminants from pulp [12]. There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectors.

Sulfide Minerals Flotation Process JXSC Machine

The feeding size of the ball mill can be smaller, the smaller, the better, grinding efficiency will much higher. So sometimes, will have 3 stages crushers in the crushing system to make a smaller feeding size for the ball mill (0-5mm or 0-8mm or 0-10mm). 2. Grinding System

How to maximize ore and grade recovery through

202036As separation efficiency of a single flotation cell is limited, multiple cells are used to improve the recovery of valuable minerals. Flotation performance matters. In today’s mining environment, every

mixedROW™ Flotation System: achieve more

The mixedROW Flotation System combines the individual benefits of nextSTEP™ flotation cells and WEMCO® flotation cells to deliver incredible results and a technologically advanced flotation solution.

Flotation Machines Mineral Processing MachineSolutions

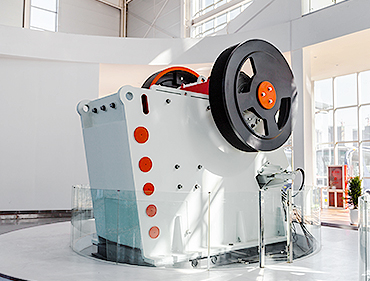

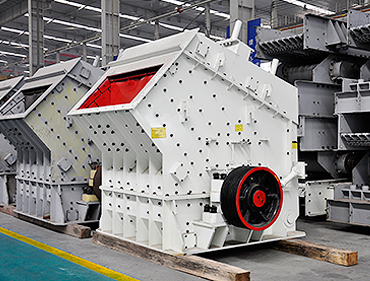

The flotation machine is composed of single or multiple flotation cells, by agitating and inflating the chemical reagent treated slurry, some mineral ore particles are adhered to the foam and float up, and then be scraped out, while the rest remains in the slurry. Types of flotation machine

RCS™ flotation machines Metso Outotec

Enhanced performance. Metso Outotec RCS™ flotation machines have made several advances in flotation design and technology. Maximize bubble-particle contact within the mechanism and the flotation tank leads to enhanced performance. Effective air dispersion and distribution throughout the cell volume helps in smooth froth surface and removal.

StackCell® Flotation Eriez

Improving fine particle flotation using the StackCell™ (raising the tail of the elephant curve) For decades, the conventional flotation machine has been the accepted tool for processing sulfide ores. As plant capacity increases, machine size has evolved to as much as 600 cubic meters to keep pace with the required retention times.

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

Mechanical flotation cells can be broken down into two broad categories based on how air is introduced to the cell. In a self aspirated flotation cell air is introduced to the slurry,

Flash Flotation with Closed Circuit Grinding

20164144 Options for Flash Flotation in a Closed Circuit Grinding Plant A greater amount of granular higher grade concentrates can be

Flash Flotation Cell Mineral ProcessingMetallurgy

201661This phenomenal recovery is made by a Unit Flotation Cell installed between the ball mill and classifier, and a coarse high grade rougher concentrate averaging 65% to 70% lead is obtained without

Flotation Test Machine

Essa® FTM101 Flotation Test Machine. The best features of FTM101 are the interchangeable parts that make it suitable for a range of metallurgical test work. Impellers, shafts and diffusers are available in various sizes

4 Common Problems and Solutions Met in the Flotation

20191129There are many types of flotation cells. But the flotation cell that most widely used in the flotation plant is the mechanical agitation flotation cell. It has complex structure, which often has the effect on the

Flotation machine, Flotation cell YouTube

2017726flotation machine works, slurry is inhaled from the bottom of the cell to the space between impellers. Meanwhile, the low-pressure air send by fan is sent to...

Flotation ANDRITZ

Inspection and maintenance-friendly construction. SelectaFlot flotation combines both primary and secondary flotation in one compact unit, resulting in advantages for inspection and maintenance. In order to save

Flash Milling inside a flotation cell Dr Johnny T. Kalala

The challenges to operate a mill inside a flotation cell are related to the: i) safety, ii) confined space, iii) lower percentage solids inside a flotation cell, iv) disturbing the zones and flow

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

Mechanical flotation cells can be broken down into two broad categories based on how air is introduced to the cell. In a self aspirated flotation cell air is introduced to the slurry,the vacuum created by the rotorusing . In a forced air flotation cell air is generated external to the cell by a low pressure blower,,and pumped down the

(PDF) Flash Milling Inside a Flotation Cell

202116The challenge s to operate a mill insid e a flotatio n cell are relate d to the: i) safet y, ii) confin ed space, iii) lower percen tage solids insi de a flotat ion cell, iv) di sturbin g the

Flash Flotation with Closed Circuit Grinding

20164144 Options for Flash Flotation in a Closed Circuit Grinding Plant A greater amount of granular higher grade concentrates can be produced and, in general, overall plant recovery is improved by

1 Froth Flotation Fundamental Principles

no flotation can occur. Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5. Figure 5: Simplified schematic of a conventional flotation cell. The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator.

Flotation Flowsheets 911metallurgist

20151214This flowsheet shows the use of a “Sub-A” Flotation Machines for selective flotation producing high grade lead and zinc products. The Unit Flotation Cell and Mineral Jig recover 73.2 percent

Continuous Flotation Cell GTEK

Working Principle. FX Flotation Machine is a kind of impeller mechanical flotation machine which mainly consist of cells, the impeller system, mainshaft system and scarping divce.. 1. To adjust the level of slurry in

Flotation Column: A Process Unit for Cleaning Up Paper

Flotation deinking is a key unit operation in most stone recycling plants for the removal of hydrophobic contaminants from pulp [12]. There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectors.

4 Common Problems and Solutions Met in the

20191129Gate structure is simple and located in the tail of flotation machine. Its main function is to adjust the level of the cell.In the process of installation and debugging, the gate is often used, so the hand wheel is

Forced-air flotation cell

Increased fine particle recovery Specifically designed to maximise fine particle recovery, the Dorr-Oliver flotation cell is the most energy efficient, technically advanced, forced-air flotation machine on the market. Its air dispersion capabilities exceed all competitive forced air designs an important consideration for fine particle recovery.

Laboratory Flotation Cell (with replaceable tanks) GTEK

D12 Lab Flotation Machine is mainly consist of the following parts: lifting mechanism, machine body, stator and impeller part, inverter and control system. All the parts are connected to the vertical column. The main

Flotation Cells Prominer (Shanghai) Mining Technology Co.,Ltd.

Based on the function of chemical reagent, it can be classified as collectors, frothers and modifiers. Technical Specifications of SF Flotation Cells: Technical specifications of XCF/KYF Series Flotation Cells Submit your requirement below for mineral processing proposal! Please contact whatsapp number via +86 for detailed information!

Flotation Test Machine

Essa® FTM101 Flotation Test Machine. The best features of FTM101 are the interchangeable parts that make it suitable for a range of metallurgical test work. Impellers, shafts and diffusers are available in various sizes and capacities to suit your needs. The flotation cells also come in four different capacities from 0.5 up to five litres.

RCS™ flotation machines Metso Outotec

Enhanced performance. Metso Outotec RCS™ flotation machines have made several advances in flotation design and technology. Maximize bubble-particle contact within the mechanism and the flotation tank leads to enhanced performance. Effective air dispersion and distribution throughout the cell volume helps in smooth froth surface and removal.

(PDF) Flash Milling Inside a Flotation Cell

202116The challenge s to operate a mill insid e a flotatio n cell are relate d to the: i) safet y, ii) confin ed space, iii) lower percen tage solids insi de a flotat ion cell, iv) di sturbin g the

Flash Milling inside a flotation cell Dr Johnny T. Kalala

The challenges to operate a mill inside a flotation cell are related to the: i) safety, ii) confined space, iii) lower percentage solids inside a flotation cell, iv) disturbing the zones and flow

1 Froth Flotation Fundamental Principles

no flotation can occur. Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5. Figure 5: Simplified schematic of a conventional flotation cell. The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator.

Flotation Test Machine

Essa® FTM101 Flotation Test Machine. The best features of FTM101 are the interchangeable parts that make it suitable for a range of metallurgical test work. Impellers, shafts and diffusers are available in various sizes

Flotation CellsMachines JXSC Machine

When the JJF mechanical agitation flotation machine is working, the rotor creates a fluid vortex inside the standpipe and the draft tube, and causes a sufficient vacuum area to induce air into the standpipe through the air inlet duct. The induced air is mixed with pulp between the impeller and stator.

Laboratory Flotation Cell (with replaceable tanks) GTEK

D12 Lab Flotation Machine is mainly consist of the following parts: lifting mechanism, machine body, stator and impeller part, inverter and control system. All the parts are connected to the vertical column. The main

Continuous Flotation Cell GTEK

FX mechanical agitated Continuous Flotation Machine is suitable for continuous flotation test or semi-industrial production test of a small amount of minerals in the laboratory by flotation method. It is made up of

Flotation Column: A Process Unit for Cleaning Up Paper

Flotation deinking is a key unit operation in most stone recycling plants for the removal of hydrophobic contaminants from pulp [12]. There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectors.

Sulfide Minerals Flotation Process JXSC Machine

The feeding size of the ball mill can be smaller, the smaller, the better, grinding efficiency will much higher. So sometimes, will have 3 stages crushers in the crushing system to make a smaller feeding size for the ball mill (0-5mm or 0-8mm or 0-10mm). 2. Grinding System

How to maximize ore and grade recovery through

202036As separation efficiency of a single flotation cell is limited, multiple cells are used to improve the recovery of valuable minerals. Flotation performance matters. In today’s mining environment, every

mixedROW™ Flotation System: achieve more

The mixedROW Flotation System combines the individual benefits of nextSTEP™ flotation cells and WEMCO® flotation cells to deliver incredible results and a technologically advanced flotation solution.

Flotation Machines Mineral Processing MachineSolutions

The flotation machine is composed of single or multiple flotation cells, by agitating and inflating the chemical reagent treated slurry, some mineral ore particles are adhered to the foam and float up, and then be scraped out, while the rest remains in the slurry. Types of flotation machine

RCS™ flotation machines Metso Outotec

Enhanced performance. Metso Outotec RCS™ flotation machines have made several advances in flotation design and technology. Maximize bubble-particle contact within the mechanism and the flotation tank leads to enhanced performance. Effective air dispersion and distribution throughout the cell volume helps in smooth froth surface and removal.

StackCell® Flotation Eriez

Improving fine particle flotation using the StackCell™ (raising the tail of the elephant curve) For decades, the conventional flotation machine has been the accepted tool for processing sulfide ores. As plant capacity increases, machine size has evolved to as much as 600 cubic meters to keep pace with the required retention times.