منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

cement crusher li ne

Cement Crushers and Lump Breakers Franklin Miler

DELUMPER® Cement Crushers and Lump Breakers have been used by cement companies worldwide to help facilitate flow and increase

Premium solutions for the cement industry

•

2 Types of Concrete Crushing Production Lines Fote

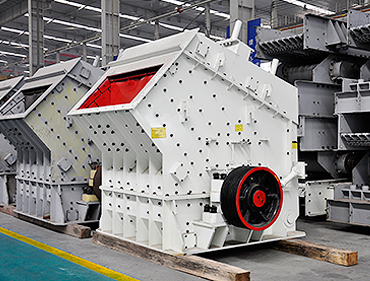

20227201. The impact crusher can effectively treat materials with large moisture content and prevent clogging of the crusher. Therefore, when the concrete has a large moisture content, the impact crusher is

5 Types of Concrete Crushers for Recycling Concrete Blocks

2023215Small concrete crushers are mainly used for crushing with small output, and most of them are jaw crushers with fixed and mobile types. The feed size of the

Cement Crusher Crushers for Cement Plant AGICO

Cement Crusher Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw

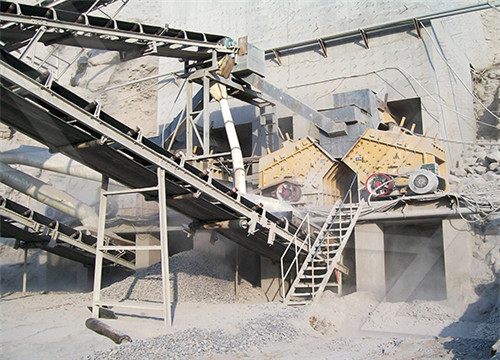

Cement Production Line Cement Manufacturing Plant AGICO

The dry process cement production line is composed of cement crushers, cement raw mill, cement kiln, cement cooler, cyclone preheater, cement silo, dust collector, etc.

Cement Euipment Overview Cement Making Machines

2019927Our cement crusher can fully crush the raw material, reduce feed size into the mill, and increase the reaction of raw material in the following cement manufacturing

Mobile Impact Crushers RUBBLE MASTER

Mobile impact crushers are used to recycle concrete and asphalt and process natural rock. They are easy to move on and between job-sites, which allows operators to crush on

Small Concrete Komplet Crushers For Sale Komplet

This compact mobile crusher works best with hard, brittle materials like concrete, softer stone, brick, cold asphalt, and other natural rocks. The jaw inlet opening is 19″ x 10″ so we recommend pre-processing material

Cement Crushers and Lump Breakers Franklin Miler

DELUMPER® Cement Crushers and Lump Breakers have been used by cement companies worldwide to help facilitate flow and increase efficency. These unit are frequently placed on the bottom of a silo to eliminate

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Compact Concrete Crushers for non-spec material (jaw or impact) start at $150,000. Small bucket crusher attachments go for a little less but are very slow and lack the ability to separate rebar efficiently. Large closed-circuit tracked impact crushers can go upwards to $750,000 $1,000,000. Of course, there are numerous options in between.

Premium solutions for the cement industry

As a full flowsheet provider with more than 135 years of experience in the cement industry, we are ready to assist you through the entire life-cycle of your plant. Products Services Solutions Filter within list Type Technology

Crushers / Lumpbreakers for CementConcrete

Cement CrushersLump Breakers. Schutte-Buffalo offers size reduction equipment ideally suited for processing cement, for both in-line or stand-alone applications. Whether your goal is to de-lump cement powder or

2 Types of Concrete Crushing Production Lines

2022720Concrete waste crushing production line The specific use of crushed concrete waste also depends on the processing effect of the selected equipment. At present, there are two kinds of crushing

Cement Euipment Overview Cement Making Machines Cement

2019927Our cement crusher can fully crush the raw material, reduce feed size into the mill, and increase the reaction of raw material in the following cement manufacturing process, reduce the energy consumption of the whole cement production line. Cement mill Cement mill is another necessary cement equipment of the cement plant.

Cement Production Line Cement Manufacturing Plant AGICO Cement

The dry process cement production line is composed of cement crushers, cement raw mill, cement kiln, cement cooler, cyclone preheater, cement silo, dust collector, etc. AGICO offers cement production lines from 1000 TPD to 10000 TPD. Skip to content Blog Contact About Cases Factory FREE QUOTATION: info@cementplantequipment Menu Menu

Cement Crusher Cement Crusher For Sale Jaw Crusher, Cone Crusher

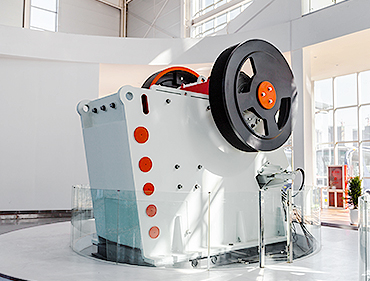

Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line.Before sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher.. The cement raw material can be crushed by many methods including pressing

Small Concrete Komplet Crushers For Sale Komplet

Its output size is 3/4″ to 3-1/4″ and has a rate of up to 34 tons per hour. The K-JC503 is a supreme choice for contractors looking to reduce excavation or construction waste on-site. The K-JC503 mobile jaw crusher creates the

Mini Cement Plant EPC Cement Line Capacity 70 600 TPD

Cement Crusher. The cement crusher is the key equipment for raw material crushing. Because the sizes of just mined limestone (raw material for most cement types) pieces are too big, we have to crush them into small particles for cement manufacturing. 2,500 tons of cement production line: 1: 3: Vietnam : 3,500 tons of cement production line

Products for cement and mining I

Quality cement and mining products from . When you choose products for cement plants and mining plants, you’ll get high-quality and durable equipment that delivers the best value long-term.

Cement Equipment Sale Cyclone Preheater|Rotary Kiln|Ball Mill|Crushers

Jaw crusher applies to the various minerals or rocks with strongest anti-crush pressure less than 250Mpa. It is widely used in mining industry, cement production line and concrete industry Hammer Crusher. Scope of application: Hammer crusher is suitable for crushing minerals of various medium and hard brittle materials. The crushed material

Crusher, Concrete For Sale 376 Listings MachineryTrader

2023131Crusher, Concrete Price: USD $45,000.00 Financial Calculator Item Location: Wingdale, New York 12594 Quantity: 1 Condition: New Year: 2020 Compare Stevee Excavation Wingdale, New York 12594 Phone: (845) 222-3137 Email Seller Video Chat Rental available! Fits to excavators. Bucket Crusher. Get Shipping Quotes Apply

Equipment > Attachments > Concrete CrushersShears

2020312Concrete CrushersShears Astec PTSC2818VM Portable High Frequency Screen Plant Astec’s PTSC plant is equipped with an 8-ft. x 18-ft. top deck and an 8-ft. x 12-ft. bottom deck.

Cement Crushers and Lump Breakers Franklin Miler

DELUMPER® LP crushers reduce cement agglomerates and lumps at an amazingly high volume. These straight-through units employ extended cutting teeth that rotate completely through a heavy bar cage. Over-sized

Products for cement and mining I

When you choose products for cement plants and mining plants, you’ll get high-quality and durable equipment that delivers the best value long-term. has more than 140 years of experience helping

Crushers / Lumpbreakers for CementConcrete

Cement CrushersLump Breakers. Schutte-Buffalo offers size reduction equipment ideally suited for processing cement, for both in-line or stand-alone applications. Whether your goal is to de-lump cement powder or

2 Types of Concrete Crushing Production Lines

2022720Concrete waste crushing production line The specific use of crushed concrete waste also depends on the processing effect of the selected equipment. At present, there are two kinds of crushing

Small Mobile Crushers, Screeners,Shredders Komplet America

Komplet small mobile crushers, screeners, and shredders help you recycle construction, demolition, and excavation waste directly on-site. (908) 369-3340 info@kompletamerica Request Quote Home

Cement Plant Cement Manufacturing Plant EPC Project

Large CapacityHigh Level Of Automation: Advanced DCS system promotes the level of automation and production capacity, also keeps thigh quality of cement. Less power consumption: Our cement production line reduce the electricity consumption by 20% ~ 30%, greatly reduce the production cost and improve the comprehensive benefit of the enterprise.

Cement Plant Equipment Cement Crusher, Cement Mill, Cement

20191121In the cement production line, limestone, clay, iron ore, coal, and other materials should be crushed. The main crushed material is limestone, there are jaw crusher, cone crusher, impact crusher, hammer crusher, and other crushers to be selected. For cement crushing plant, vibration feeder and vibrating screen will be equipped together.

Mini Cement Plant EPC Cement Line Capacity 70 600 TPD

The cement crushers that can be used in mini cement plants are hammer crusher, jaw crusher, roll crusher, cone crusher, impact crusher, etc. Conveying Equipment The conveying equipment is an indispensable auxiliary device for material transportation in

Cement Equipment Sale Cyclone Preheater|Rotary

Jaw crusher applies to the various minerals or rocks with strongest anti-crush pressure less than 250Mpa. It is widely used in mining industry, cement production line and concrete industry Hammer Crusher.

Equipment > Attachments > Concrete CrushersShears

2020312Concrete CrushersShears Astec PTSC2818VM Portable High Frequency Screen Plant Astec’s PTSC plant is equipped with an 8-ft. x 18-ft. top deck and an 8-ft. x 12-ft. bottom deck.

Hammer Crusher Working Principle AGICO

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is

SICEMENT Automation Cement Siemens Global

The Schelklingen cement plant has been operated for more than 100 years and currently provides kiln production capacity of approx. 3,500 tons of clinker. Since 1987 HeidelbergCement has been using different CEMAT versions in this cement plant location. Especially for the new kiln line, the latest state-of-the-art process control system.

Choosing a mobile impact crusher for recycling what you

2021312"The impact crusher's ability to handle steel-reinforced concrete, along with custom options, such as and -waste removal systems, washing systems and more, has enabled recyclers to create much higher quality end products, and crush and process materials previously deemed only waste, or too difficult to process." Built for

Concrete Processing Attachments Enhance Recycling Savings

202092MB Crusher manufactures a line of crusher buckets that ranges from a less than 1-ton model with a production rate of 10 cubic meters/hour to a more than 10-ton model with production that exceeds