مسكن

>

primary diagrams of copper crusher

مسكن

>

primary diagrams of copper crusher

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

primary diagrams of copper crusher

Industrial Solutions Gyratory crushers ThyssenKrupp

crusher configuration. The feed material should be at least 20% smaller than the width of the feed open ing. Arrangement drawing with fitting dimensions and loads on request.

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary

(PDF) SIZE REDUCTION BY CRUSHING METHODS

201734The fol lowing diagram shows the stages in opera tion of size . Copper Ore, Zinc Ore and Manganese Ore. jaw crusher and

Crushing Plant FlowsheetDesign-Layout Mineral

Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig. 1, which is a diagrammatic view of a two-stage arrangement. The ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary breaker, the latter being of the jaw type in the case of a small plant a911metallurgist:13

Types of Crushers: What You Need to Know Machinery Partner

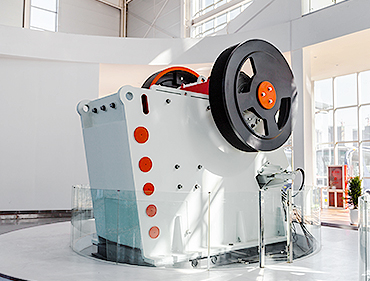

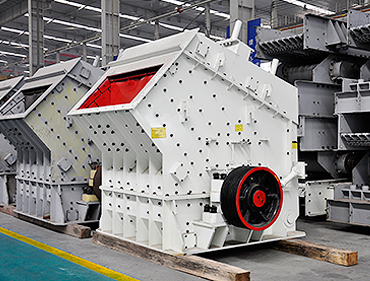

Primary crushing produces materials ranging from 1500mm to 350mm, on average. The two main types of primary crushers are: Jaw Crushers: large amounts of material are fed

Gyratory Crusher Explained saVRee

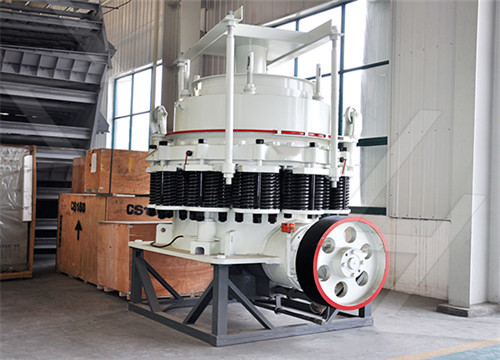

A primary crusher is designed to receive run-on-mine (ROM) rocks directly from the mines. Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory

Primary Crushing Mineral ProcessingMetallurgy

2016226The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which

Primary Diagrams Of Copper Crusher

Diagram of superior primary gyratory crusherrimary diagrams of copper crusher gaps primary crusher flow diagram lets take a look at the primary components of

primary diagrams of copper crusher avisizano.it

primary diagrams of copper crusher copper grinding and crushing diagram acelowcarbon Pyrometallurgical Process Flow Diagram for Copper Ore Mill

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

Industrial Solutions Jaw crushers ThyssenKrupp

primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveying. For these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: single-toggle jaw crushers

EXPLODED VIEW MODEL 4150/4160 Holley

147 Secondary Power Valve Assembly 148 Secondary Power Valve Gasket 149 Secondary Metering Body Gasket 150 Secondary Metering Body Assembly 151 Secondary Metering Body Plate 152 Secondary Metering Body Plate Gasket 153 Main Metering BodyPlugs Assembly Secondary 154 Secondary Metering Body Screw 155 H.I.C. Cover Screw

SecondaryTertiary Crushing Circuits Mineral Processing

2015724This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high enough to require that the crushing be done in stages. Again the ore will come from a Primary crusher and be scalped. The coarse material will be crushed by the secondary crusher.

Types of Crushers: What You Need to Know Machinery Partner

Primary crushing produces materials ranging from 1500mm to 350mm, on average. The two main types of primary crushers are: Jaw Crushers: large amounts of material are fed into the “V-shaped” jaw of this crusher and are reduced using compressive force. One side of the V remains stationary while the other side of the V swings against it.

Chapter 7 Energy Use in the Copper Industry Princeton

Energy Use in the Copper Industry All aspects of copper production require energy, whether i n the form of electricity, explosives, or hydrocarbon fuels (diesel, gasoline, natural gas, fuel oil, coal, coke), or as the energy equivalent of materials consumed (e. g., chemicals and steel grinding media). In 1977, the primary copper in-

181 Process Flow Diagram (PFD) Symbols for Engineers

Process Flow Diagram Equipment Symbols. Flow chart symbols use different shapes to represent different components, such as equipment, valves, instruments, and piping flow. There is a standardized set of flowchart symbols. Process Flow Diagram equipment symbols include centrifuges and heat exchangers.

Primary Crushing Mineral ProcessingMetallurgy

2016226The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant.

ru/crushiers copper miningpdf.md at main businessgitv/ru

Contribute to businessgitv/ru development by creating an account on GitHub.

primary diagrams of copper crusher avisizano.it

primary diagrams of copper crusher copper grinding and crushing diagram acelowcarbon Pyrometallurgical Process Flow Diagram for Copper Ore Mill grindingWikipedia A mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting Get price .

Cone Crusher an overview ScienceDirect Topics

Figure 5.3 is a schematic diagram of a cone crusher. they are used for comminution of porous copper cake. A Fritsch jaw crusher with maximal feed size 95 Hammer crushers are used either as a one-step primary crusher or as a secondary crusher for products from a primary crusher. They are widely used for crushing of hard metal scrap for

Primary Crusher an overview ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

Rimfire Firing-Pin Indent Copper Crusher (part 1) 2017-02-03

201723A single copper indent crusher is placed in the firing chamber of a firearm and the trigger is pulled, causing the firing pin to strike and leave an indent mark on the rim area of the copper crusher. The copper crusher is then removed and the indentation measured (Fig. 6). The indentation must measure 0.014 inch (read to the nearest 0.0005

Jaw Crusher Explained saVRee

The main components of a typical jaw crusher are: Fixed Jaw Moving Jaw Jaw Liners Main Shaft (Pitman Assembly) Drive PulleyFlywheel Toggle Plate (s)Tension Rods/Assembly Jaw Crusher with Single Toggle Plate Design Jaw Crusher Classification Jaw crushers are classified based on the position of the pivoting swing jaw.

Cone Crusher an overview ScienceDirect Topics

Figure 5.3 is a schematic diagram of a cone crusher. they are used for comminution of porous copper cake. A Fritsch jaw crusher with maximal feed size 95 Hammer crushers are used either as a one-step primary crusher or as a secondary crusher for products from a primary crusher. They are widely used for crushing of hard metal scrap for

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

Industrial Solutions Jaw crushers ThyssenKrupp

primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveying. For these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: single-toggle jaw crushers

Mineral Processing Plant Design University of Technology, Iraq

The largest primary gyratory crushers cost US $2 million or more, while overall crushing plant costs can be as high as $18 million. It’s necessary therefore to estimate crusher installation costs based on equipment costs plus the following direct costs, including construction contractor indirects: • Earthworks • Mechanical • oncrete

SecondaryTertiary Crushing Circuits Mineral Processing

2015724This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high enough to require that the crushing be done in stages. Again the ore will come from a Primary crusher and be scalped. The coarse material will be crushed by the secondary crusher.

181 Process Flow Diagram (PFD) Symbols for Engineers

Process Flow Diagram Equipment Symbols. Flow chart symbols use different shapes to represent different components, such as equipment, valves, instruments, and piping flow. There is a standardized set of flowchart symbols. Process Flow Diagram equipment symbols include centrifuges and heat exchangers.

Chapter 7 Energy Use in the Copper Industry Princeton

Energy Use in the Copper Industry All aspects of copper production require energy, whether i n the form of electricity, explosives, or hydrocarbon fuels (diesel, gasoline, natural gas, fuel oil, coal, coke), or as the energy equivalent of materials consumed (e. g., chemicals and steel grinding media). In 1977, the primary copper in-

Primary Crusher SelectionDesign Mineral Processing

20151223Primary crushers with crush run-of-mine rock from blast product size to what can be carried by the discharge conveyor or fit/math the downstream process. A typical example of primary crushing is reducing top-size from 900 to 200 mm. In Selecting a primary crusher you need to worry about these requirements:

Rimfire Firing-Pin Indent Copper Crusher (part 1) 2017-02-03

201723The crusher system uses a small bar (crusher bar) of copper (Fig. 4) mounted between a stationary anvil and a small cylindrical piston fitted over a hole drilled in the barrel of a test gun (Fig. 5). Upon firing, the crusher bar is compressed slightly due to the force of the blast on the cylinder, which is transferred to the bar.

primary diagrams of copper crusher avisizano.it

primary diagrams of copper crusher copper grinding and crushing diagram acelowcarbon Pyrometallurgical Process Flow Diagram for Copper Ore Mill grindingWikipedia A mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting Get price .

Primary Crusher an overview ScienceDirect Topics

In general, coal crushers are categorized into two types and three types of primary crushers, as follows: Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

Diagram of a Jaw Crusher [image: (135-5-9)] Jaw Crusher Fundamentals Vertical Height = 2 x Gape Width of Jaw > 1.3 x Gape < 3.0 x Gape Throw = 0.0502 (Gape) 0.85 Gape is measured in meters. Jaw crusher action Jaw Crusher Sizes and Power Ratings Size is specified in terms of the gape and width, typically listed as gape x width.

Crushing 101 ? Masaba Manufacturing

2019104JAW CRUSHER. 8:1 maximum reduction ratio for compression crushing, this is normally used as a primary crusher. Jaws perform well in many materials. Yields low wear cost per ton in hard abrasive deposits, minimal fines but produces little finished (under 1”) product which places more load on the crushers downstream in the circuit.

Metso SUPERIOR® gyratory crushers Metso Automation PDF

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine Metso’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily