مسكن

>

why do you need to crush iron ore bering rock

مسكن

>

why do you need to crush iron ore bering rock

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

why do you need to crush iron ore bering rock

Rock Crushing Process in Mining Mineral Processing

2015718First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher

why is there a need to crush the ore bearing rock iron

201668Crusher Wikipedia, the free encyclopediawhy do you need to crush iron ore bering rock — China Mining Equipment why is there a need to crush the ore

why is there a need to crush the ore bearing rock iron

the need to crush the bearing iron ore rocks why is there a need to crush the ore bearing rock iron why crush the iron ore bearing rock why is there a need to.

why is there a need to crush iron ore bearing rock

rock separetor grizly in tamil nadu india Solution for ore, * Why Is There A Need To Crush Iron Ore Bearing Rock. Vibrating Screen Manufacturers India,Industrial Vibrating

Why Is There A Need To Crush Iron Ore Bearing Rock

the need to crush iron ore bearing rock. why is there a need to crush iron ore bearing rock. There is a hoary myth among old prospectors that ore bodies widen and get richer

why do you need to crush iron ore bering rock

why is bauxite rock crushed, why crush ore bearing rock crusher South Africa. ilmenite, iron ore, why would you need a rock crusher Go to Product Center. need

why do you need to crush iron ore bering rock

2016/01/01A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product size was

why is there a need to crush the ore bearing rock iron

SmartLearnerwhy iron ore is crushed with cok. 33 the need to crush the ore bearing rock this makes the ore more manageable and increases the exposed surface area for the

why do you need to crush iron ore bering rock

AG mills crush the ore without the need for iron or steel grinding media. They are used when the ore is hard enough for the tumbling ore to grind itself. In SAG milling, ∼0.15 m

Sedimentary rock Iron-rich sedimentary rocks Britannica

Almost all sedimentary rocks are iron-bearing in the sense that mudrocks, sandstones, and carbonates typically have an iron content of several percent. Nevertheless, sedimentary rocks in which the proportion of iron exceeds 15 percent are separately categorized as iron-rich. Two major types of iron-rich sedimentary rocks are recognized: (1

Iron ore Wikipedia

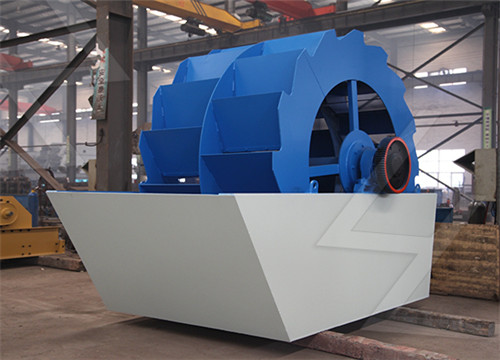

Mining of banded iron formations involves coarse crushing and screening, followed by rough crushing and fine grinding to comminute the ore to the point where the crystallized magnetite and quartz are fine enough that

Iron Ore: Sedimentary Rock Pictures, Definition

Earth's most important iron ore deposits are found in sedimentary rocks. They formed from chemical reactions that combined iron and oxygen in marine and fresh waters. The two most important minerals in these

Rock Crushing Process in Mining Mineral

2015718First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher “breaks it and the fine material produced will drop through the gap between the

Crushing in Mineral Processing

20151226The only reason why you would use an impact mill/crusher or a hammer mill on a high-silica rock is because it might be sticky in nature and rich in clay. Such high abrasion/high silica

Which Crusher Is Suitable for Your Hard Rock? Fote

2023215Protodyakonov rock classification is based on Protodyakonov scale to classify the hard rock and soft rock. f = 15-20: Extremely strong rocks, such as very strong granite, limestone, quartzite,

why crush the iron ore bearing rock -china

the need crush the ore bearing rock of iron Grinding Mill, the need crush the ore bearing rock of iron. Posted at: July 27, 2012. In the iron ore crushing plant, it can crush iron ore into small sizes. Go to Product Center. why crush the iron ore bearing rock, Why Crush The Iron Ore Bearing Rock.

why is there a need to crush iron ore bearing rock

rock separetor grizly in tamil nadu india Solution for ore, * Why Is There A Need To Crush Iron Ore Bearing Rock. Vibrating Screen Manufacturers India,Industrial Vibrating Screen It was only Rock 'n Go to Product Center. Iron Ore Homestead, Iron ore mining methods vary by the type of ore being mined.

why do you need to crush iron ore bering rock

AG mills crush the ore without the need for iron or steel grinding media. They are used when the ore is hard enough for the tumbling ore to grind itself. In SAG milling, ∼0.15 m 3 of 13 cm diameter iron or steel balls are added into the mill per 0.85 m 3 of ore (i.e., 15 vol.% “steel”) to assist grinding.

Taconite Wikipedia

Taconite (/ ˈ t æ k ən aɪ t /) is a variety of iron formation, an iron-bearing (over 15% iron) sedimentary rock, in which the iron minerals are interlayered with quartz, chert, or carbonate.The name "taconyte" was

Crusher an overview ScienceDirect Topics

13.3.1 Crushing Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. 13.3.1.1 Primary Crusher

Extracting gold from rock OpenLearn Open University

2019830This would be useful because, for the same effort, we can use twice the weight to crush our rocks. Powdering the rock The next step was to take the crushed pieces of rock and make them even smaller. We used a heavy metal rod (a broken half shaft from a four wheel drive) and smashed the small bits of rock in a saucepan.

Mineral processing metallurgy Britannica

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy. The primary operations are comminution and concentration, but

Energy and Environmental Profile of the U.S. Mining

The characteristics of iron-bearing ores vary geographically. Specifically, magnetite and hematite are the main iron-bearing ores in the Lake Superior district and in the northeastern United States, while hematite and hematite-magnetite mixtures tend to be found in ores in Alabama and the Southwest. 4.1 Process Overview 4.1.1 Iron Ore Mining

Sedimentary rock Iron-rich sedimentary rocks Britannica

Almost all sedimentary rocks are iron-bearing in the sense that mudrocks, sandstones, and carbonates typically have an iron content of several percent. Nevertheless, sedimentary rocks in which the proportion of iron exceeds 15 percent are separately categorized as iron-rich. Two major types of iron-rich sedimentary rocks are recognized: (1

Iron ore Wikipedia

Mining of banded iron formations involves coarse crushing and screening, followed by rough crushing and fine grinding to comminute the ore to the point where the crystallized magnetite and quartz are fine enough that

Iron Ore: Sedimentary Rock Pictures, Definition

Earth's most important iron ore deposits are found in sedimentary rocks. They formed from chemical reactions that combined iron and oxygen in marine and fresh waters. The two most important minerals in these

Rock Crushing Process in Mining Mineral

2015718First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher “breaks it and the fine material produced will drop through the gap between the

Which Crusher Is Suitable for Your Hard Rock? Fote

2023215Protodyakonov rock classification is based on Protodyakonov scale to classify the hard rock and soft rock. f = 15-20: Extremely strong rocks, such as very strong granite, limestone, quartzite,

why crush the iron ore bearing rock -china

the need crush the ore bearing rock of iron Grinding Mill, the need crush the ore bearing rock of iron. Posted at: July 27, 2012. In the iron ore crushing plant, it can crush iron ore into small sizes. Go to Product Center. why crush the iron ore bearing rock, Why Crush The Iron Ore Bearing Rock.

why is there a need to crush iron ore bearing rock

rock separetor grizly in tamil nadu india Solution for ore, * Why Is There A Need To Crush Iron Ore Bearing Rock. Vibrating Screen Manufacturers India,Industrial Vibrating Screen It was only Rock 'n Go to Product Center. Iron Ore Homestead, Iron ore mining methods vary by the type of ore being mined.

why do you need to crush iron ore bering rock

AG mills crush the ore without the need for iron or steel grinding media. They are used when the ore is hard enough for the tumbling ore to grind itself. In SAG milling, ∼0.15 m 3 of 13 cm diameter iron or steel balls are added into the mill per 0.85 m 3 of ore (i.e., 15 vol.% “steel”) to assist grinding.

Taconite Wikipedia

Taconite (/ ˈ t æ k ən aɪ t /) is a variety of iron formation, an iron-bearing (over 15% iron) sedimentary rock, in which the iron minerals are interlayered with quartz, chert, or carbonate.The name "taconyte" was

Crusher an overview ScienceDirect Topics

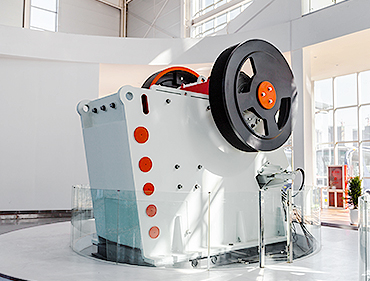

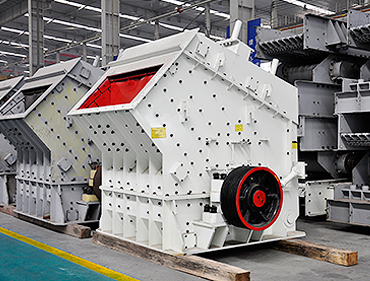

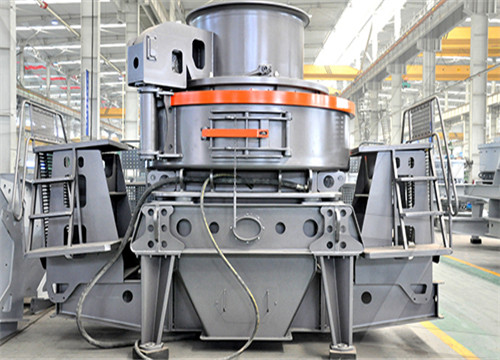

13.3.1 Crushing Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. 13.3.1.1 Primary Crusher

How does a Rock Crusher Work Jaw Crusher 911Metallurgist

20211122Designed up to one-third longer, it exerts greater pressures in the upper portion of the crushing chamber, distributes crushing action more evenly. The result is a gradual reduction of ore to the choking point, and increased capacity! Metal is concentrated at points that make for the most effective jaw design.

Extracting gold from rock OpenLearn Open University

2019830This would be useful because, for the same effort, we can use twice the weight to crush our rocks. Powdering the rock The next step was to take the crushed pieces of rock and make them even smaller. We used a heavy metal rod (a broken half shaft from a four wheel drive) and smashed the small bits of rock in a saucepan.

Energy and Environmental Profile of the U.S. Mining

The characteristics of iron-bearing ores vary geographically. Specifically, magnetite and hematite are the main iron-bearing ores in the Lake Superior district and in the northeastern United States, while hematite and hematite-magnetite mixtures tend to be found in ores in Alabama and the Southwest. 4.1 Process Overview 4.1.1 Iron Ore Mining

Mineral processing metallurgy Britannica

Most ores, however, are made up of hard, tough rock masses that must be crushed before the valuable minerals can be released. In order to produce a crushed material suitable for use as mill feed (100 percent of the pieces must be less than 10 to 14 millimetres, or 0.4 to 0.6 inch, in diameter), crushing is done in stages.