مسكن

>

engineeribg materials for ball mill shell in processing gold

مسكن

>

engineeribg materials for ball mill shell in processing gold

منتج

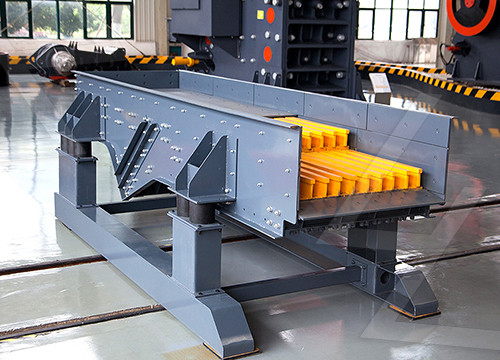

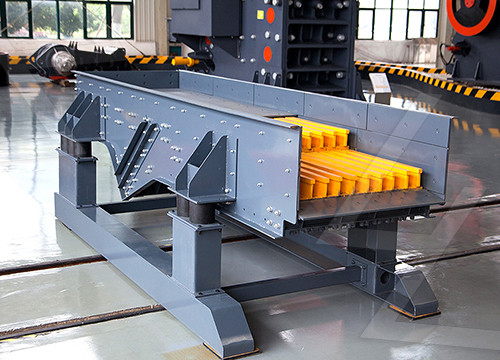

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

engineeribg materials for ball mill shell in processing gold

sbm/sbm engineeribg materials for ball mill shell in

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Using Ball Mills to Extract Raw Gold from Ores

The Purpose of MillingThe Function of A Ball MillBreaking Down Oresfrom Ore Chunks to Fines For Processing

To perform its functions, the ball mill operates on the principle of impact and attrition. This principle entails that the balls are dropped from near the top of the shell in order to bring about size reduction impact. The major components of the ball mill include a shell that is hollow and is suspended on its axis to bring about rotation. The axis...

Ball Mills Mineral ProcessingMetallurgy

Ball Mill MaintenanceInstallation ProcedureThe working principle of ball mill Meetyou Carbide•

Ball Mill an overview ScienceDirect Topics

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it.

Ball mill Wikipedia

OverviewDescriptionWorkingApplicationsAdvantages of the ball millVarietiesSee also

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls. An internal cascading effect reduces the

Wikipedia CC-BY-SA :8

Ball milling: a green technology for the preparation

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective

the importance of shell plates inside a ball mill for gold

Contribute to jidafang2022/en development by creating an account on GitHub.

Mill Shell an overview ScienceDirect Topics

Grinding Mills. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 7.2.3 Construction of Mills Shell. Mill

Standards for design and sizing ball mill GrindingClassification

I am searching for both aspects, design and sizing ball mill (calculation of thickness of shell,Ø of shell,) . my request is there is a standards to determine : diameter and length

Shell-supported Ball Mills: Grinding Technology on a Large Scale

A large and increasing number of references show that shell-supported ball mills work efficiently and reliably under the most stringent operating conditions. Their design

Ball Mill an overview ScienceDirect Topics

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it. Ball mills are classified as attritor, horizontal, planetary, high energy, or shaker. View chapter Purchase book Mechanical Crushing and Grinding

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

Improved mill control at Lihir Gold Mine in Papua New Guinea

20181025The Lihir Gold project: Process plant design, Minerals Engineering, 6 (8-10)1037. Napier-Munn, T.J 2009. An Introduction to Comparative Statistics and Experimental Design for Minerals Engineers (2nd Edition), Julius Kruttschnitt Mineral Research Centre, University of Queensland. Napier-Munn, T.J, Morrell, S, Morrison, R.D,

8 Pieces of Gold Mining Equipment That Help You Recover More Gold

2023215It utilizes the specific gravity difference between gold and other minerals to separate gold. It works better when processing placer gold. It is also used to separate the iron, tin, wolframite, tantalum, niobium, chromite, rutile, monazite, etc. The material size ranges from 0.6-0.03mm. Compared with the shaker table, it is lighter and occupies

Mining/Ore Milling Mt Baker Mining and Metals

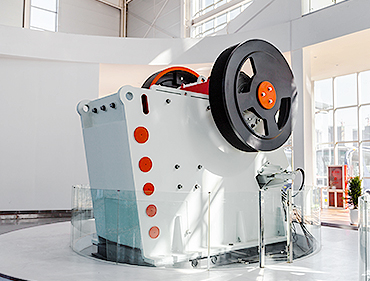

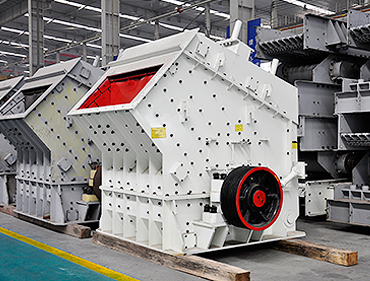

The hammer mill or ball mill takes the <3/4″ discharge from the jaw crusher and pulverizes it to liberate the values in the ore (usually gold), and one of them is a component of our Turn-Key Ore Processor. The size of the powder from a hammer mill is controlled by the size of the openings in the screen, and the discharge is processed on the

Small Ball Mill 911Metallurgist

The CIW is a Small Ball Mill that’s belt driven, rigid bearing, wet grinding, trunnion or grate discharge type mill with friction clutch pulley and welded steel shell. The 7 and 8 foot diameter mills are of flange ring construction with cut

Ball milling: a green technology for the preparation and

The use of ball milling to obtain cellulose nanocrystals was also explored by the group of Yu, who extracted CNCs from ball-milled via a multi-step process. 40 Douglas-Fir chips were firstly hammer-milled to s, which were then treated using a planetary ball mill at 270 rpm. This process was followed by enzymatic hydrolysis

Mill liners Metso Outotec

Metso Outotec designs mill linings for optimal grinding performance. We offer fit for purpose liners for all types of mills, including SAG mills, AG mills, ball mills, rod mills, and pebble mills. Our liners are designed to fit the specific requirements of each mill, taking into account factors such as mill size, speed, charge, expected service

Ball Mill MaintenanceInstallation Procedure

20161019Mill SHELL LinerHEAD Liners Grate discharge heads for ball mills are completely assembled in the shop, with grates, clamp bars, pan liners, and center discharge liners in place. Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion

OPTIMIZATION OF MILLING PROCESS PARAMETERS A

of Beryllium Copper Alloy Using end mill. Taguchi analysis was performed for analyze the result data. They selected cutting speed, feed and depth of cut as process parameters and material removal rate, surface roughness and machining time as quality parameters. The experiments were conducted by using L 9 orthogonal array. The results show that the

Ball Milling an overview ScienceDirect Topics

Ball milling, a shear-force dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO2) or steel balls), acting as grinding media and rotating shell to create centrifugal force.

XMQL Pilot Ball-Rod Mill JXSC Machine

XMQL Pilot Ball-Rod Mill with spiral classifier conducts laboratory grinding process, researches and determines ore grinding capacity indicators in mineral feasibility study tests, and grinding fine materials for mineral processing plants or other industries. and grinding fine materials for mineral processing plants or other industries

Grinding Mills Mineral Processing Equipment CITIC HIC

High cost-effectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept, and 60 years of

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

Ball Mills 【Capacity】 0.2-90 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】0.075-0.4mm 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

Ball Mill Liners Multotec

Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates. The MultoMet range utilises Hardox 500 wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance.

8 Pieces of Gold Mining Equipment That Help You Recover More Gold

2023215It utilizes the specific gravity difference between gold and other minerals to separate gold. It works better when processing placer gold. It is also used to separate the iron, tin, wolframite, tantalum, niobium, chromite, rutile, monazite, etc. The material size ranges from 0.6-0.03mm. Compared with the shaker table, it is lighter and occupies

Ball Milling an overview ScienceDirect Topics

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore,

Mining/Ore Milling Mt Baker Mining and Metals

The hammer mill or ball mill takes the <3/4″ discharge from the jaw crusher and pulverizes it to liberate the values in the ore (usually gold), and one of them is a component of our Turn-Key Ore Processor. The size of the powder from a hammer mill is controlled by the size of the openings in the screen, and the discharge is processed on the

Ball milling: a green technology for the preparation and

The use of ball milling to obtain cellulose nanocrystals was also explored by the group of Yu, who extracted CNCs from ball-milled via a multi-step process. 40 Douglas-Fir chips were firstly hammer-milled to s, which were then treated using a planetary ball mill at 270 rpm. This process was followed by enzymatic hydrolysis

Mill liners Metso Outotec

Steel, Poly-Met™, Megaliner™, Rubber and Orebed™ mill liners for all mill types Features What makes your grinding mill unique? Experience from over 8,000 mills world-wide combined with the market’s most comprehensive offering mean we can select the optimal solution for your specific mill. Contact our sales experts Performance targets:

XMQL Pilot Ball-Rod Mill JXSC Machine

XMQL Pilot Ball-Rod Mill with spiral classifier conducts laboratory grinding process, researches and determines ore grinding capacity indicators in mineral feasibility study tests, and grinding fine materials for mineral processing plants or other industries. and grinding fine materials for mineral processing plants or other industries

Standards for design and sizing ball mill Grinding

I am searching for both aspects, design and sizing ball mill (calculation of thickness of shell,Ø of shell,) . my request is there is a standards to determine : diameter and length of ball mill the thickness of the shell and other parameters needed for construction. I hope that my request is clear . Abdellatif

OPTIMIZATION OF MILLING PROCESS PARAMETERS A

of Beryllium Copper Alloy Using end mill. Taguchi analysis was performed for analyze the result data. They selected cutting speed, feed and depth of cut as process parameters and material removal rate, surface roughness and machining time as quality parameters. The experiments were conducted by using L 9 orthogonal array. The results show that the

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

【 Wet Grinding 】 Gold, chrome, tin, coltan, tantalite, silica sand, lead, pebble, and the like mining application. 【 Dry Grinding 】 Cement, building stone, power, etc. 【 Grinding Media Ball 】 Steel ball, manganese, chrome, ceramic ball, etc. 【 Common Steel Ball Sizes 】 40mm, 60mm, 80mm, 100mm, 120mm.

Ball Mill Linings Multotec

Excellent sealing properties to eliminate gold lock-up; Ball mills are used in mineral processing and pharmaceutical applications. 2. How does a ball mill work? The impact of the balls that drop from the top of the shell therefore reduce the size of the material at the bottom of the shell. The balls within the ball mill machine are made

Grinding Mills Mineral Processing Equipment CITIC HIC

High cost-effectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept, and 60 years of

Innovative methods of ball milling to grind activated carbon as an

201781PDF On Aug 1, 2017, L S Godse and others published Innovative methods of ball milling to grind activated carbon as an electrode material for enhancing the performance of ultracapacitor Find

Ball Mill an overview ScienceDirect Topics

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it.

Ball mill Wikipedia

OverviewDescriptionWorkingApplicationsAdvantages of the ball millVarietiesSee also

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls. An internal cascading effect reduces the

Ball milling: a green technology for the preparation

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective

the importance of shell plates inside a ball mill for gold

Contribute to jidafang2022/en development by creating an account on GitHub.

Mill Shell an overview ScienceDirect Topics

Grinding Mills. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 7.2.3 Construction of Mills Shell. Mill

Standards for design and sizing ball mill GrindingClassification

I am searching for both aspects, design and sizing ball mill (calculation of thickness of shell,Ø of shell,) . my request is there is a standards to determine : diameter and length

Shell-supported Ball Mills: Grinding Technology on a Large Scale

A large and increasing number of references show that shell-supported ball mills work efficiently and reliably under the most stringent operating conditions. Their design

Ball Mill an overview ScienceDirect Topics

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it. Ball mills are classified as attritor, horizontal, planetary, high energy, or shaker. View chapter Purchase book Mechanical Crushing and Grinding

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

Improved mill control at Lihir Gold Mine in Papua New Guinea

20181025The Lihir Gold project: Process plant design, Minerals Engineering, 6 (8-10)1037. Napier-Munn, T.J 2009. An Introduction to Comparative Statistics and Experimental Design for Minerals Engineers (2nd Edition), Julius Kruttschnitt Mineral Research Centre, University of Queensland. Napier-Munn, T.J, Morrell, S, Morrison, R.D,

8 Pieces of Gold Mining Equipment That Help You Recover More Gold

2023215It utilizes the specific gravity difference between gold and other minerals to separate gold. It works better when processing placer gold. It is also used to separate the iron, tin, wolframite, tantalum, niobium, chromite, rutile, monazite, etc. The material size ranges from 0.6-0.03mm. Compared with the shaker table, it is lighter and occupies

Mining/Ore Milling Mt Baker Mining and Metals

The hammer mill or ball mill takes the <3/4″ discharge from the jaw crusher and pulverizes it to liberate the values in the ore (usually gold), and one of them is a component of our Turn-Key Ore Processor. The size of the powder from a hammer mill is controlled by the size of the openings in the screen, and the discharge is processed on the

Small Ball Mill 911Metallurgist

The CIW is a Small Ball Mill that’s belt driven, rigid bearing, wet grinding, trunnion or grate discharge type mill with friction clutch pulley and welded steel shell. The 7 and 8 foot diameter mills are of flange ring construction with cut

Ball milling: a green technology for the preparation and

The use of ball milling to obtain cellulose nanocrystals was also explored by the group of Yu, who extracted CNCs from ball-milled via a multi-step process. 40 Douglas-Fir chips were firstly hammer-milled to s, which were then treated using a planetary ball mill at 270 rpm. This process was followed by enzymatic hydrolysis

Mill liners Metso Outotec

Metso Outotec designs mill linings for optimal grinding performance. We offer fit for purpose liners for all types of mills, including SAG mills, AG mills, ball mills, rod mills, and pebble mills. Our liners are designed to fit the specific requirements of each mill, taking into account factors such as mill size, speed, charge, expected service

Ball Mill MaintenanceInstallation Procedure

20161019Mill SHELL LinerHEAD Liners Grate discharge heads for ball mills are completely assembled in the shop, with grates, clamp bars, pan liners, and center discharge liners in place. Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion

OPTIMIZATION OF MILLING PROCESS PARAMETERS A

of Beryllium Copper Alloy Using end mill. Taguchi analysis was performed for analyze the result data. They selected cutting speed, feed and depth of cut as process parameters and material removal rate, surface roughness and machining time as quality parameters. The experiments were conducted by using L 9 orthogonal array. The results show that the

Ball Milling an overview ScienceDirect Topics

Ball milling, a shear-force dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO2) or steel balls), acting as grinding media and rotating shell to create centrifugal force.

XMQL Pilot Ball-Rod Mill JXSC Machine

XMQL Pilot Ball-Rod Mill with spiral classifier conducts laboratory grinding process, researches and determines ore grinding capacity indicators in mineral feasibility study tests, and grinding fine materials for mineral processing plants or other industries. and grinding fine materials for mineral processing plants or other industries

Grinding Mills Mineral Processing Equipment CITIC HIC

High cost-effectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept, and 60 years of

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

Ball Mills 【Capacity】 0.2-90 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】0.075-0.4mm 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

Ball Mill Liners Multotec

Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates. The MultoMet range utilises Hardox 500 wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance.

8 Pieces of Gold Mining Equipment That Help You Recover More Gold

2023215It utilizes the specific gravity difference between gold and other minerals to separate gold. It works better when processing placer gold. It is also used to separate the iron, tin, wolframite, tantalum, niobium, chromite, rutile, monazite, etc. The material size ranges from 0.6-0.03mm. Compared with the shaker table, it is lighter and occupies

Ball Milling an overview ScienceDirect Topics

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore,

Mining/Ore Milling Mt Baker Mining and Metals

The hammer mill or ball mill takes the <3/4″ discharge from the jaw crusher and pulverizes it to liberate the values in the ore (usually gold), and one of them is a component of our Turn-Key Ore Processor. The size of the powder from a hammer mill is controlled by the size of the openings in the screen, and the discharge is processed on the

Ball milling: a green technology for the preparation and

The use of ball milling to obtain cellulose nanocrystals was also explored by the group of Yu, who extracted CNCs from ball-milled via a multi-step process. 40 Douglas-Fir chips were firstly hammer-milled to s, which were then treated using a planetary ball mill at 270 rpm. This process was followed by enzymatic hydrolysis

Mill liners Metso Outotec

Steel, Poly-Met™, Megaliner™, Rubber and Orebed™ mill liners for all mill types Features What makes your grinding mill unique? Experience from over 8,000 mills world-wide combined with the market’s most comprehensive offering mean we can select the optimal solution for your specific mill. Contact our sales experts Performance targets:

XMQL Pilot Ball-Rod Mill JXSC Machine

XMQL Pilot Ball-Rod Mill with spiral classifier conducts laboratory grinding process, researches and determines ore grinding capacity indicators in mineral feasibility study tests, and grinding fine materials for mineral processing plants or other industries. and grinding fine materials for mineral processing plants or other industries

Standards for design and sizing ball mill Grinding

I am searching for both aspects, design and sizing ball mill (calculation of thickness of shell,Ø of shell,) . my request is there is a standards to determine : diameter and length of ball mill the thickness of the shell and other parameters needed for construction. I hope that my request is clear . Abdellatif

OPTIMIZATION OF MILLING PROCESS PARAMETERS A

of Beryllium Copper Alloy Using end mill. Taguchi analysis was performed for analyze the result data. They selected cutting speed, feed and depth of cut as process parameters and material removal rate, surface roughness and machining time as quality parameters. The experiments were conducted by using L 9 orthogonal array. The results show that the

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

【 Wet Grinding 】 Gold, chrome, tin, coltan, tantalite, silica sand, lead, pebble, and the like mining application. 【 Dry Grinding 】 Cement, building stone, power, etc. 【 Grinding Media Ball 】 Steel ball, manganese, chrome, ceramic ball, etc. 【 Common Steel Ball Sizes 】 40mm, 60mm, 80mm, 100mm, 120mm.

Ball Mill Linings Multotec

Excellent sealing properties to eliminate gold lock-up; Ball mills are used in mineral processing and pharmaceutical applications. 2. How does a ball mill work? The impact of the balls that drop from the top of the shell therefore reduce the size of the material at the bottom of the shell. The balls within the ball mill machine are made

Grinding Mills Mineral Processing Equipment CITIC HIC

High cost-effectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept, and 60 years of

Innovative methods of ball milling to grind activated carbon as an

201781PDF On Aug 1, 2017, L S Godse and others published Innovative methods of ball milling to grind activated carbon as an electrode material for enhancing the performance of ultracapacitor Find