مسكن

>

iron ore processing equipments

مسكن

>

iron ore processing equipments

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

iron ore processing equipments

Iron Ore Processing Equipment FEECO International Inc.

Iron Processing Equipment We can supply high quality equipment, as well as complete systems, all engineered to meet your precise project

Iron processing Definition, History, Steps, Uses,Facts

•

Iron ore pelletizing Metso Outotec

•

Mineral Processing Equipment Multotec

Leading range of cyclones, spirals, magnetic separators, flotation components, centrifuges, samplers, filter pressesslurry pumps

Iron Processing Equipment, Process Flow, Cases JXSC

The former mainly selects magnetite ore, and the latter is mainly used for sorting hematite, mixed iron ore and weak magnetic ore. 6.2 Magnetic separation cation reverse flotation process The grade of iron

Iron Ore Processing Prominer (Shanghai) Mining

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic

Top 10 Best Mineral Processing Equipment Fote Machinery

Materials: Iron ore, tin, tungsten, tantalum, niobium, etc. Processing capacity: 15-48 t/h 8. Classification Equipment Spiral classifier: Price: 2, 000 $/ Set (lowest price) Classifying

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

Iron Ore Processing Home

This is where the processing plant of Scandinavia’s biggest iron ore producer is located, with a facility for direct loading of iron ore pellets onto ships. The existing plant has a processing rate of 6,000 t/h, and a new

Iron Ore Processing Plants North West Bond Equipment

This technology is superior to any other concentration technology package and offer significantly improved processing efficiencies for various minerals that include iron ore,

Iron processing Definition, History, Steps, Uses,Facts

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a

Reliable equipment for iron ore mines

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials

Iron Processing Equipment, Process Flow, Cases

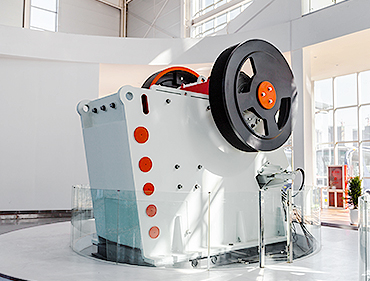

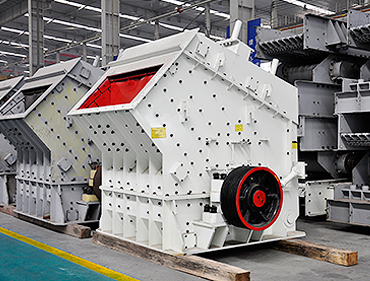

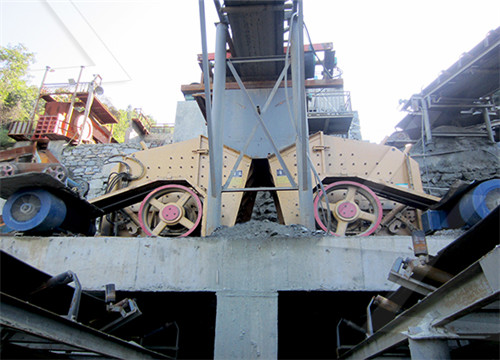

The main iron ore mining equipment includes jaw crushers, ball mills, magnetic separators, spiral classifiers, jig concentrators and related auxiliary equipment such as ore dryers. Jaw crusher reduces the hard iron ore

Ore Processing Multotec

MineralOre Processing. Ore processing is a chain of processing applications which treats run of mine to firstly high-grade concentrate (concentration of ores) and then to the pure mineral or metal. The refined ore is used in manufacturing equipment and machinery in numerous industries, or is for sale in industry, commerce and consumer

Dry Iron Ore Beneficiation ST Equipment

Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits. STET has evaluated several iron ore tailings and run of mine

Iron Ore Processing Home

This is where the processing plant of Scandinavia’s biggest iron ore producer is located, with a facility for direct loading of iron ore pellets onto ships. The existing plant has a processing rate of 6,000 t/h, and a new

Iron Ore Beneficiation Mineral Processing

Iron ore beneficiation process including ilmenite, magnetite, limonite etc ore processing plants and equipment as per customer's needs. Skip to content. Mineral Processing. Email Us [email protected] +86- . Tel or WhatsApp Chat . Mineral Processing. This is a 500tph iron rock ore processing plant, main machines including:

IRON ORE PROCESSING Gongyi Jingying Machinery

The grade of iron ore refers to the mass fraction of iron element in iron ore, say, the iron content. For example, if the grade of iron ore is 62, the mass fraction of iron element is 62%. Through crushing, grinding, magnetic separation, flotation separation and re-election, the iron can be selected from the natural iron ore. Iron ore

20tph China Factory Mining Recovery Machineries For Processing

20tph China Factory Mining Recovery Machineries For Processing The Zircon Sand,Find Complete Details about 20tph China Factory Mining Recovery Machineries For Processing The Zircon Sand,Machineries For Processing The Zircon Sand,Iron Ore Concentration Plant,Iron Processing Plant Machine from Supplier or Manufacturer-Jiangxi Province

IJERPH Free Full-Text Environmental Protection or Development

2023124The change from quantity-based taxation to price-based taxation of iron ore resources is an important measure for China to implement the goal of carbon peaking and carbon neutralization, and to achieve green economic recovery. To explore the policy’s effectiveness in playing its tax function, and improving the environment and production

The six main steps of iron ore processing Multotec

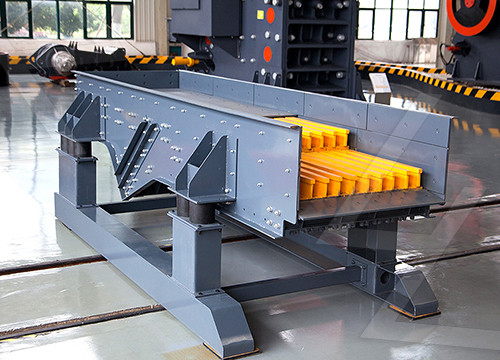

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Extraction of Iron, Iron Mining, Iron Ore Processing Xinhai Mining

At present, iron ore resources are decreasing day by day, which is characterized by more lean ore than rich ore, more associated ore and complex ore composition. Xinhai Mining, as a mineral processing equipment manufacturer with over-20-year experience, provides responsible iron ore processing technologies by different type of iron ores.

Home Yantai Jinpeng Mining equipment, ore dressing process

Jinpeng Mining Machinery is a high-technological enterprise that integrates research, design, manufacture, installation and commissioning, personal training, after-sales service etc, depending on the advanced equipments and abundant technological strength, we could offer one-stop service and ensure the high rate recovery of clients' mine.

Iron processing Definition, History, Steps, Uses,Facts

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a

Miningmineral processing solutions Malvern Panalytical

2017322It ensures a homogenous output towards the beneficiation plant and avoids the processing of low grade ore or waste. Our solutions can be employed for continuous, non-contact monitoring of elemental and mineralogical composition as well as the prediction of process relevant parameters in a large range of mining applications such as iron,

Reliable equipment for iron ore mines

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials

Ore Processing Multotec

MineralOre Processing. Ore processing is a chain of processing applications which treats run of mine to firstly high-grade concentrate (concentration of ores) and then to the pure mineral or metal. The refined ore is used in manufacturing equipment and machinery in numerous industries, or is for sale in industry, commerce and consumer

Dry Iron Ore Beneficiation ST Equipment

Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits. STET has evaluated several iron ore tailings and run of mine

Iron Ore Processing Home

This is where the processing plant of Scandinavia’s biggest iron ore producer is located, with a facility for direct loading of iron ore pellets onto ships. The existing plant has a processing rate of 6,000 t/h, and a new

Iron Ore Beneficiation Mineral Processing

Iron ore beneficiation process including ilmenite, magnetite, limonite etc ore processing plants and equipment as per customer's needs. Skip to content. Mineral Processing. Email Us [email protected] +86- . Tel or WhatsApp Chat . Mineral Processing. This is a 500tph iron rock ore processing plant, main machines including:

IRON ORE PROCESSING Gongyi Jingying Machinery

Suitable for processing nonferrous metal minerals such as iron ore, gold ore Application Mineral crushing, Ore processing Equipments Jaw crusher, cone crusher, vibrating feeder, vibrating screen, belt conveyor. Live chat Send Message Send email Introduction of iron ore Iron usually exists in compound, especially in iron oxide.

IJERPH Free Full-Text Environmental Protection or Development

2023124The change from quantity-based taxation to price-based taxation of iron ore resources is an important measure for China to implement the goal of carbon peaking and carbon neutralization, and to achieve green economic recovery. To explore the policy’s effectiveness in playing its tax function, and improving the environment and production

20tph China Factory Mining Recovery Machineries For Processing

20tph China Factory Mining Recovery Machineries For Processing The Zircon Sand,Find Complete Details about 20tph China Factory Mining Recovery Machineries For Processing The Zircon Sand,Machineries For Processing The Zircon Sand,Iron Ore Concentration Plant,Iron Processing Plant Machine from Supplier or Manufacturer-Jiangxi Province

Extraction of Iron, Iron Mining, Iron Ore Processing Xinhai Mining

At present, iron ore resources are decreasing day by day, which is characterized by more lean ore than rich ore, more associated ore and complex ore composition. Xinhai Mining, as a mineral processing equipment manufacturer with over-20-year experience, provides responsible iron ore processing technologies by different type of iron ores.

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Mining separation and sorting equipment for processes in the mining

Dry coal beneficiation with sorting systems; wet drum magnetic separators for traditional processing (de-stoning for greater efficiency) To your solution Tramp removal sorting Overhead suspension magnets reliably remove tramp iron from bulk materials. They thus protect crushers, grinders and other processing plant from wear and damage.